If the person whom you decided to hire with clinker to decorate the facade says that it will help you to buy cheap material, and glue for clinker tiles is not needed at all, it will be completely controlled by a simple cement mortar - run away from it, nothing good will come of it in the end. Once you have decided to invest in material of this class, follow all the requirements of the laying technology, including those that are presented to the choice of glue, otherwise you will only get disappointed.

What features of clinker tiles affect the choice of glue

The main factor that affects the choice of glue for clinker tiles is that its moisture absorption does not exceed 2% (we are now talking about a real clinker tile, not cheap fakes). In addition, the expansion coefficient of the tile, due to its particularly dense structure, differs significantly from the performance of the wall material, therefore, under the influence of temperature and other factors, problems may arise with maintaining the integrity of the cladding.

It is these properties of clinker tiles that determine the properties of the adhesive used. First of all mixtures, on which are supposed to be laying the cladding, should be characterized by high elasticity. The use of hard mixtures (type SM-11) is unacceptable. In addition, glue suitable for the specific installation conditions should be selected.

which are supposed to be laying the cladding, should be characterized by high elasticity. The use of hard mixtures (type SM-11) is unacceptable. In addition, glue suitable for the specific installation conditions should be selected.

The influence of the place of operation of clinker tiles

As an axiom, you must accept the following rule - glue should only be used for the conditions for which it is intended. Mixtures for internal work should not be used for facade cladding. In terms of performance, all adhesives can be divided into the following types:

- Adhesive for interior use under normal conditions.

- Mixtures used for facing surfaces with elevated temperatures (heat-resistant, heat-resistant, etc.).

- Adhesives for rooms with high humidity (waterproof).

- Glue for facing facades (the main quality is frost resistance).

- A mixture intended for the installation of acid-resistant tiles.

- Universal mixtures can be used both indoors and outdoors.

Detailed information on the scope of use of mixtures must be indicated

manufacturer on the packaging. Choosing adhesive for laying clinker tiles, Be sure to familiarize yourself with all its characteristics.

The main features in choosing adhesive for clinker tiles

When choosing an adhesive mixture for clinker tiles, you need to take into account the level of moisture absorption. High-quality certified reliable clinker products should be fixed on an adhesive basis, in which this indicator does not exceed 2%.

In addition, it is necessary to take into account the fact that the density of clinker tiles does not coincide with the density of facade walls, therefore, under the influence of temperature changes or any other factors, the integrity of the facing materials or the wall as a whole can be violated. Clinker tile glue must have high elasticity. It is strictly forbidden to use glue mixtures of a rigid type.

The main requirements for adhesive for clinker cladding plates:

- elasticity,

- high viscosity

- moisture resistance

- high adhesion strength

- high adhesion

- resistance to the appearance of fungus, mold, the accumulation of microbes.

Types and types of glue for clinker tiles

Experts recommend selecting both the adhesive mixture and grout for clinker tiles at the same time from one manufacturer. This improves the quality and reliability of the cladding. This is explained by the use of different components in the production of certain mixtures. So, a disagreement of manufacturers can lead to the loss of the necessary properties and characteristics or to any other undesirable consequences.

In addition to the well-known brands offering adhesive bases for clinker tiles, it is recommended to inquire about other manufacturers that are popular in other regions. Today, the market has several of the most famous and most sought after brands:

- Extrabond 131 - It is used both for interior decoration and for facades. Frost resistance - 50 cycles.

- RKS - the adhesive mixture is suitable for cladding structures in which high humidity is inherent.

- Ceresit SM-117 - one of the most common adhesive solutions. It has medium elasticity, but can be used in almost any place (facades, pools, interior decoration, etc.).

- Baumacol flex - glue has a high level of elasticity. It is used for facing fireplaces, stoves and any other complex structures.

- Knauf - this glue mixture has a separate classification for internal, and a separate - for outdoor use.

- Litoflex K 80 - differs in good adhesion, glue can be applied for internal and external works.

Among the masters there is a separation of adhesive compositions for clinker plates as follows:

- One-component (homogeneous). This material is already sold in the form of a ready-to-paste mixture. A big drawback of this type of glue is its long drying time.

- Cement. These mixtures were popular several years ago, when there were practically no alternatives to them. This is a classic type of mortar: the cement composition is diluted with plasticizers, water-retaining components and dispersion additives.

- Polyurethane (epoxy). This glue is prepared on the basis of two other components. Although the cost of such adhesive mixtures is an order of magnitude higher than the rest, their reliability and strength are also several times more.

The method of applying glue to clinker tiles

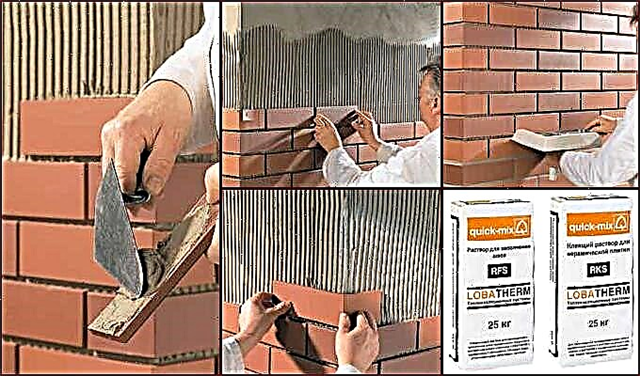

The glue base is applied using a notched trowel, leaving a kind of grooves. The height of the teeth of such a spatula should be 6-8 mm, for a thicker layer, which should hold heavier tiles, use a spatula with teeth 10-12 mm long.

A small layer of glue is also applied to the wall. However, here you need to correctly calculate your strength and speed of laying tiles. The adhesive mixture dries within 20-30 minutes, and if during this time you do not have time to treat the area with the adhesive applied, this may cause a deterioration in adhesion.

It should also be borne in mind that during the scorching sun or strong winds, the drying process of the glue is somewhat accelerated, therefore it is better to apply the glue to a smaller area. Clinker tile laying is recommended to be carried out on a lace, which is stretched along each row. If the lining is carried out in this way, then, naturally, it will be much more convenient to apply the adhesive base for the tile.

Preparation of adhesive for clinker tiles

To prepare glue for clinker, you need to stock up on a plastic bucket (any other round container), a construction mixer, a special nozzle and water (any other liquid). When cooking, you need to use a liquid of that temperature, which is advised by the manufacturer of the selected brand of glue (as a rule, the manufacturer advises the temperature regime from +5 to +20 ° C).

It is necessary to collect liquid in the prepared container, and gradually, stirring, add a dry glue mixture. Upon receipt of a viscous substance, you need to mix the composition with a construction mixer (about 800 rpm), wait 5-7 minutes, then mix again.

The resulting mixture can be used to fix the clinker tiles for 2 hours, therefore, the facade area should be calculated.

IMPORTANT! Any debris or dirt particles must be removed from the dry glue mixture, as this can speed up the setting time of the composition. Before mixing, it is recommended to thoroughly rinse the container, and also use only clean liquid.

Clinker tile mixes

What mortar to use for laying this material? If you decide to save money and use a mixture of cement with sand, then the service life of the cladding can be very short. After all, the moisture absorption of the tile is only 2%, and the expansion coefficients of it and the wall material are different, which most often leads to a violation of the integrity of the coating.

You can avoid this situation if you use special glue for tiles. However, it should be chosen taking into account the features of both the facing material itself, and the specifics of its place of application, installation conditions. An ideal option is a composition with high elasticity, while the use of hard mixtures is considered by experts as unacceptable. We examined what is best to glue the clinker tiles, now we will move on to studying the characteristics of the compositions.

You can avoid this situation if you use special glue for tiles. However, it should be chosen taking into account the features of both the facing material itself, and the specifics of its place of application, installation conditions. An ideal option is a composition with high elasticity, while the use of hard mixtures is considered by experts as unacceptable. We examined what is best to glue the clinker tiles, now we will move on to studying the characteristics of the compositions.

Types of glue and their features

A wide variety of mixtures used for laying facing materials forces the buyer to carefully choose one of them. So experts conditionally divide such formulations into three main groups:

To understand which of the mixtures will allow you to achieve the best result when laying, you should find out not only their composition and basic characteristics. One of the easiest formulations to use is uniform glue for clinker steps. Usually it enters the distribution network in the form of a pasty mixture ready for use. However, this glue has one drawback - a long drying time.

The most popular are polyurethane compounds. Such glue usually consists of two components and has a high cost. But at the same time, in terms of reliability and strength of installation of the cladding, he has no equal.

Polymer compositions are implemented in two versions:

Each of the considered types of glue is characterized by certain parameters:

- Frost resistance

- Hardening time

- Scope of application (for indoor or outdoor use).

Most popular blend brands

The composition for the installation of facing materials, as a rule, is acquired in conjunction with a grout. Experts believe that they should be performed by one manufacturer. In this case, the same components will be used in the glue and grout, which will improve the quality of the installation, as well as the reliability of the lining during operation.

While the use of materials from various manufacturers can lead to the loss of their certain properties, as well as other undesirable results.

Some of the most popular brands of adhesive bases for clinker tiles in the domestic market are:

Some of the most popular brands of adhesive bases for clinker tiles in the domestic market are:

The first composition is the products of a Russian manufacturer. They are intended for use both indoors and for decoration of facades. The glue has frost resistance up to 50 cycles.

The composition of RKS is used for laying clinker in rooms with a maximum level of humidity. It has high adhesion and has water repellent properties. Its use is allowed when performing both internal and external cladding.

The most common and popular is the adhesive brand Ceresit CM. Despite the medium elasticity of the composition, it is excellent for finishing facades, interior spaces and even swimming pools.

Watch a video about Ceresit CM products:

The highest elasticity of Quickum Baumacol clinker tile adhesive. Therefore, it is recommended to use it for facing complex structures, in particular stoves and fireplaces.

The manufacturer Knauf, unlike the rest, produces two types of mixtures: for indoor and outdoor use.

What to consider when choosing glue

One of the most important requirements is the compliance of the composition with the conditions in which its use is expected. So mixtures intended for internal work should not be used when facing the facade and vice versa. Based on its performance, it is classified as intended for:

- Interior decoration under normal conditions,

- Surfaces that heat up during operation,

- High humidity rooms

- Facades

- Universal.

More accurate and detailed information about the scope and method of application of a particular composition is provided by the manufacturer on the packaging. And choosing glue, you need to take into account the features of the object in which it is supposed to be used, as well as carefully study the attached instructions.

Watch the video, the criteria for choosing the best glue:

Many companies produce several types of adhesive for frost-resistant clinker tiles, one of which is budget mixes. They usually differ slightly in quality from analogues, but have a lower cost.

Among the main parameters that are sure to pay attention when choosing glue are the following:

- Elasticity,

- Moisture resistant

- Adhesion,

- Viscosity,

- Graspability

- Frost resistance

- Wide range of applications,

- Protection against fungus and mold.

If all of the above characteristics are present in the composition that you decided to buy, then laying clinker tiles with its use will allow you to get a reliable and high-quality lining. Ideally, the adhesive for such a material should withstand the impact of any climatic influences. Otherwise, even when absorbing a minimum amount of moisture, freezing the composition will lead to its destruction and violation of the integrity of the lining

The main requirement for glue for clinker

Clinker is a low-porous, dense material. A quality clinker even makes a clean chime when tapped on it like metal. Due to this, the material has a very low moisture absorption, up to 3%, which is due to its durability, because the main destructive force for building materials is climatic influences.

However, the construction of the building itself is usually composed of materials with much more prosaic characteristics, therefore, with differences in temperature and humidity, the base and cladding will behave very differently due to different expansion coefficients. Therefore, the glue mixture must carry the function of a damper, equalizing the voltage difference and at the same time preserving its integrity. Based on this, the main requirement for adhesive for clinker tiles is maximum elasticity, which budget cement mixes do not satisfy in any way.

Basic rules for choosing glue for clinker

The choice of adhesive for clinker tiles depends on the type of product and the conditions under which they will be used in the future. Therefore, it is important to have complete information about the cladding area:

- external or internal

- relative humidity of the zone

- exposure to high temperatures

- vertical arrangement of facing or floor.

When choosing adhesives from European manufacturers, it is worth paying attention to the labeling of the class of the mixture according to DIN EN 12004. Class C1 and C2 are assigned to cement-based mixtures, D1 and D2 to polymer, R1 and R2 to quick-hardening (reaction) mixtures, usually to epoxy basis. The number indicates the degree of adhesion of the mixture. Additionally, according to DIN EN 12002, the adhesive elasticity is regulated: if the marking is S1 (the hardened layer bends at least 2.5 mm) or S2 (at least 5 mm), then you are dealing with flexible mixtures that are ideal for cladding facades prone to climatic sinusoids.

Facade cladding

In addition to elasticity, fast setting is important for vertical cladding, otherwise the tile will simply “float”.In addition, moisture resistance and frost resistance of the compounds, resistance to ultraviolet and antiseptic additives that protect the walls from the development of the fungus are important requirements. Mixtures used to equip clinker window sills should satisfy the same conditions. The ideal representative of this group of compounds is Quick-mix RKS adhesive, designed for cladding walls with clinker and ceramics.

Wall covering

For internal work, the environmental friendliness of the composition and good adhesion to most types of surfaces come to the fore, and the lining of showers and work areas of kitchens will require moisture-resistant properties of the mixture. An unprecedented model for this type of work can be the waterproof adhesive composition FK 100 from Quick-mix. Due to its good adhesion during thin-layer application, this solution is very economical and perfectly complements the inherent vitality of clinker tiles.

Facing the floor and steps

The surface of the floor is considered stable, therefore, when laying floor clinker tiles and steps, the elasticity of the adhesive composition is not so important as its adhesion, the mechanical strength of the resulting layer, its moisture and frost resistance. Quick-mix experts recommend the use of cement based adhesives FK 100 (indoor floor) or FK 300 (indoor and outdoor) for these purposes.

Separately, it should be noted that it is advisable to purchase adhesives along with grouts of joints of the same manufacturer so that the conflict of components during their interaction does not lead to a deterioration in the performance of the lining.

By choosing the “right” adhesive mixture, you give the acquired clinker a chance to demonstrate his unique viability to several generations of your family and become its full relic.

Famous brands of adhesive for clinker tiles

Here, first of all, it is worth saying that in addition to well-known brands, there are a number of manufacturers whose products are popular in certain regions. Moreover, it can even surpass the quality of known mixtures. Therefore, before choosing a glue, be sure to analyze the local market, collect as much information as possible about the offers available, take an interest in reviews about them. With the availability of goods of really proper quality, there is a real opportunity to save some on local mixtures, because branded products are much more expensive.

If we talk about more famous adhesive mixtures, the results of the studies identified the following, most popular formulations (a place in the list does not mean more recognition, the information is not promotional in nature):

- Trademark "Quick-mix", RKS glue. It can be used for interior and exterior decoration, frost-resistant, suitable for facing rooms with high humidity.

- Terta, mixture of Extrabond 131. It can also be used for facades and interior decoration. Frost resistance is slightly lower (50 cycles).

- Clay tile adhesive Ceresit SM-117. This TM is one of the most famous, glue SM-117 can be used even when arranging the basin territories, finishing facades, has medium elasticity.

- Knauf compositions also do not need a special introduction. Fliesemkleber mixture is used for interior decoration; it will not be suitable for facades and damp rooms.

- Baumit offers Baumacol Flex adhesive, which is highly elastic, can be used for facing stoves, fireplaces, and any complex surfaces.

- Litokol company produces a mixture of Litoflex K 80, designed for cladding facades and interior, is characterized by good adhesion.

When choosing a mixture of a particular manufacturer, think about purchasing a grout of the same company. So you can significantly improve the quality and improve the properties of the cladding. The fact is that different companies use different components for their mixtures, the use of dissimilar materials can lead to undesirable consequences.

By the way, when choosing, take an interest in the availability of budget analogs of the proposed mixtures, many companies practice the production of cheaper compositions that differ slightly in quality. And besides everything else, take care of high-quality preparation of the base, or even the best glue will fall off with the tiles.

DESCRIPTION

Clinker tiles are in regular demand in the market. This is due to its excellent performance. However, the purchase of this material is a significant budget item, so many buyers seek to optimize their own costs. And while reducing costs, they start with glue for clinker tiles, acting far from always consciously - on the advice of friends, the recommendations of craftsmen or store consultants. This article will discuss how to make the right choice and avoid the annoying mistakes that will make themselves felt during operation.

Important material properties

Clinker is characterized by density and minimal porosity. When tapped, material from reliable manufacturers makes a sound that resembles metal ringing. In addition, clinker tiles are characterized by low water absorption, which is due to its long service life.

However, the building can be built from low-quality materials subject to negative environmental influences: changing seasons, temperature changes, etc. Due to different expansion coefficients, the base of the building and cladding can behave unpredictably. That is why glue for clinker tiles should perform a shock-absorbing function. The mixture should maintain the integrity of the facing material and offset the voltage difference.

That is why experts believe that a good adhesive for clinker tiles should have the following properties:

- elasticity. This quality is not characteristic of simple cement mixtures,

- water resistance

- good adhesion and adhesion to the surface,

- frost resistance, ability to tolerate temperature changes,

- ability to resist fungus and mold.

How to choose the right mixture?

Experts recommend paying attention to a number of criteria that will help narrow down the search for a mixture:

- where the cladding will be carried out (inside the building or outside),

- tile layout - floor or wall,

- humidity test

- temperature operating conditions.

Also, when choosing tile adhesive for clinker tiles, you should carefully read the packaging. In particular, note the labeling. So, the literal value indicates the basis of the mixture used:

- D1 and D2 - polymer. The adhesive is delivered ready-made. Before use, you must carefully move the contents of the jar,

- R1 and R2 - epoxy (most often). It is characterized by rapid hardening,

- C1 and C2 - cement. Viscous mixtures used for both outdoor and indoor use. Contain plasticizers and modifying additives.

- The European classification DIN EN 12002 regulates the elasticity of the adhesive. So, using a material with the number S1, a deflection of not less than 2.5 mm after its final hardening is achieved, S2 - not less than 5. Such materials are perfect for facade work.

- The number in the label indicates the degree of adhesion of the material.

What to use for facing clinker steps and floors?

Experts attribute these surfaces to stable. Therefore, the glue used for their lining must be durable, moisture and frost resistant, as well as good adhesion. These qualities have adhesive for clinker tiles brand Pereo. It has a cement base and is characterized by versatility: it can be used for both indoor and outdoor use.

What can be used for facade cladding?

If clinker is used for wall decoration, give preference to fast-setting elastic compounds. Otherwise, the finish is deformed. Also, high-quality adhesive for clinker tiles must be characterized by resistance to the formation of mold and fungus, moisture, ultraviolet radiation.

Features of internal work

For the interior, it is best to use glue for clinker tiles with good adhesion and a safe composition. It is important that during operation it does not emit toxic fumes. If it is required to carry out facing of a fireplace, use heat resisting structures. For work in the kitchen, in bathrooms and in other rooms with high humidity, use waterproof compounds.

Compositions with good adhesion set well even when applying a thin layer. This quality provides economical material consumption.

Clinker is a material with outstanding qualities. It is environmentally friendly, provides reliable protection against negative environmental factors, has an attractive appearance. However, these properties are disclosed only with the correct selection of adhesive for clinker tiles and observing the laying technology. We hope that the recommendations given in the article will help you make the right choice.