In the photo: it is impossible to apply liquid wallpaper without a primer

Did you know that a primer for liquid wallpaper should be applied without fail? Any violations lead to the fact that the composition can exfoliate in separate areas or a dark base is visible from under the coating. To prevent this from happening, just use the recommendations in this review.

The process of applying the soil is simple, but there are a lot of nuances, without which it is impossible to prepare the walls well

Liquid wallpaper fits well only on properly processed walls

Stage 1 - collecting the necessary materials and tools

First of all, find out what primer is needed for liquid wallpaper. I will talk about 4 options, each of which is suitable for work and is suitable for certain rooms.

Silk Plaster primer is specifically designed for walls that will be finished with liquid wallpaper

| Soil type | Its features |

| Special compounds | These are solutions that were originally designed for silk plaster. The most famous of them is Silk Plaster, although there are others. I did not notice much difference in quality between specialized and conventional options. Only here the price of this type of product is several times higher - for 5 liters you have to pay about 1000 rubles |

| Acrylic Compositions | The most common and popular option, which is suitable for most reasons. Primers penetrate deep into the surface, strengthening it and reducing absorption. The ideal solution for dry rooms, the cost for a can of 10 liters is 500-700 rubles |

| Water repellents | Liquid wallpaper does not tolerate high humidity, so if there is a danger of moisture penetration from the walls, they need to be treated with a special composition. The most popular option is called "Aquastop" and is sold as a concentrate. The dilution proportions are indicated on the package and depend on the type of wall and its strength. The price for packing 3 sheets is about 800 rubles |

| Adhesive compounds | If the walls are smooth and poorly absorb moisture (most often it is concrete), then they need to be prepared in their own way. In this case, adhesive primer is used; it lays well even on smooth surfaces. The composition has a quartz filler, which makes the surface more embossed, improving the adhesion of the finish. Packaging 15 kg from the brand "Ceresite" will cost about 1000 rubles |

Standard formulations are great for our work.

The concentrate is good in that it can be diluted in the right amount on the spot.

Hello. I would like to ask. On the package of soil-concentrate, the proportion of dilution with water is not indicated. Please tell me how much water should be added. weight of soil-concentrate 1.4 kg.

Arthur, usually a concentrated primer, is diluted 1: 5. In general, dilute the composition so that it is convenient to apply with a brush or roller (similar to paint).

kitchen wall partially oil paint. partially putty. how to prepare for the primer. there are areas whitewashed with lime. thanks.

Irina, whitewashing must be removed, it is best to wash off. Then these areas should be primed and putty with the same putty as the finished areas. Then the base is primed two more times. After that, you can paint it.

Tell me, please, and after coating with water-based paint (white), do you need to prime the wall again or apply liquid wallpaper directly to the water-based paint?

what primer to buy for liquid wallpaper

Elena, a primer for liquid wallpaper is needed not only for high-quality adhesion (adhesion) of the coating and base. First of all, its task is to prevent the penetration of moisture. It is necessary to use the material where “high hydrophobicity” is indicated in the operational characteristics. It is recommended to process in 2-3 layers. So that the protective coating does not lose its properties, each subsequent layer is applied only after the previous one has completely dried. For liquid wallpaper, the following primers are mainly used: Acrylic - the best option. Differs in easy drawing, fast drying, uniformity of a layer. Deeply penetrating - it is well absorbed into the base, after drying it forms a strong moisture-proof film. One of the advantages is the ability to smooth out imperfections in the base (pores, bumps). Quartz - are made using quartz dust. Give the treated surface a slight roughness, which in turn contributes to a better quality application of liquid decorative coatings.

What is liquid wallpaper

Material for applying liquid wallpaper is produced from cellulose fibers, dyes and other modifying additives.

The dry mixture resembles sawdust in structure.

The material is mixed with water immediately before application, following the manufacturer's recommendations.

When applied, it forms a strong seamless surface that is resistant to mechanical stress.

To prevent peeling of the decorative coating, the walls for liquid wallpaper must be primed.

Primer Application

Application of primers is necessary for strong adhesion of the wall surface and decorative finishing coatings.

Primer for liquid wallpaper performs the following tasks:

- increases the adhesion of the base and finish,

- provides uniform application, uniformity and color matching of liquid wallpaper,

- prevents the formation of mold and mildew,

- strengthens and strengthens the foundation,

- improves appearance

- extends the life of the coating,

- levels roughnesses and roughnesses of the basis under finishing,

The composition fills in microcracks and pores, which contributes to the saving of liquid wallpaper and facilitates their application.

Choose a primer

The primer for wall impregnation for liquid wallpaper is chosen, depending on the base material and the type of decorative compositions.

From the correct choice of impregnation depends on the life and quality of the decorative coating.

Primers for liquid wallpaper are available in different types:

- Acrylic Suitable for the treatment of cement and concrete surfaces, drywall, cinder blocks and bricks.

Deeply penetrating the surface, increase the strength, water resistance and durability of the coating, improve the appearance. Prevent the formation of fungus and mold.

Deep penetration primers are suitable for hardening porous, highly absorbent surfaces.

Perhaps application in damp rooms.

The active components of the mixture penetrate into the pores of the base, impregnating and holding them together.

Acrylic impregnations are versatile and affordable.

- Adhesive. Designed for processing dense concrete and cement surfaces, poorly absorb moisture. Impregnations create a rough layer that promotes good adhesion to the decorative coating.

The roughness of the soil gives quartz sand, a small amount of which is located in the primer.

- Alkyd. They are used for processing wooden substrates. Not suitable for application on concrete and plaster.

- Water repellents. Deep penetration formulations designed for rooms with high humidity.

They have a high water-repellent ability, strengthens the base and reduces the consumption of finishing materials. Resistant to alkalis and salts.

Prevent the penetration of moisture from walls and the environment. Suitable for impregnation of concrete, plaster, putty, fiberboard, chipboard, GVL.

There are special formulations designed for application under silk plaster. By technical and operational characteristics, they do not differ from ordinary primers, but in many ways they are superior in cost.

If possible, buy a primer of the same manufacturer as liquid wallpaper.

Manufacturers equip expensive options for decorative coatings with impregnations and liquid for diluting dry components.

On the packaging of decorative mixtures, the manufacturer gives recommendations for their preparation, indicates which primer is needed for applying to a specific type of liquid wallpaper.

Surface requirements

The base for decorative wall decoration should be strong, durable, dry and clean.

The surface should not absorb water and change color when liquid spills on it.

On the plane intended for decoration, the presence of foci of mold, fungal lesions and efflorescence is not allowed.

Foundation preparation

Surface preparation for priming is an obligatory stage of finishing work.

We perform the work in the following sequence:

- We remove the old decorative finish, remove the peeling plaster sections.

- We level the walls with a layer of plaster or putty.

- We embroider cracks and seal with a solution.

- We cover the structures with an antiseptic solution twice, to prevent the development of fungus and mold, if these components are not present in the primer of your choice.

Application of primer on various surfaces

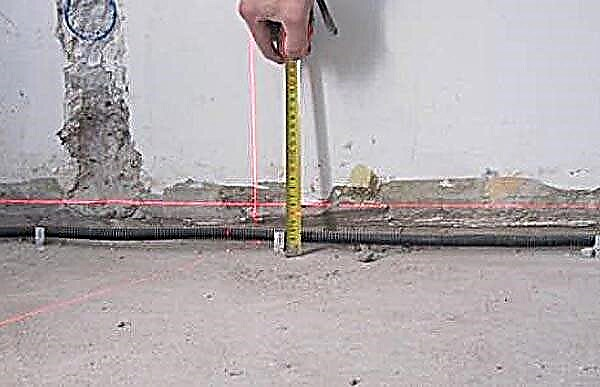

Priming work on any bases must be carried out at low humidity and a positive temperature from 5 to 25 degrees.

If the temperature is too high, the primers dry quickly, not having time to absorb to a sufficient depth.

The technology of applying the primer depends on the base material and the choice of the composition of the primer mixture.

When preparing a solution from a dry or concentrated mixture, follow the manufacturer's instructions.

Ready-to-work composition is thoroughly mixed until smooth.

Thorough mixing requires an adhesive primer containing quartz filler, which settles to the bottom.

Pour the solution into the paint tray.

We cover the wall with a uniform layer of primer, using a roller or brush, moving sequentially from top to bottom.

We apply the second impregnation layer after the first one has completely dried, but not earlier than after 4 hours. Drying time of a certain composition is indicated on the package. It is possible to start the subsequent finishing no earlier than in one day.

Priming with a roller provides a more uniform layer and allows more economical use of impregnation.

When processing dark substrates or color unevenness, it is better to paint the walls with water-based paint in white, or in the color of decorative finishes.

Painted walls

Primed walls, painted with water-based compounds, are better with acrylic impregnation.

Surfaces painted with oil paint are treated with adhesive impregnations. They will roughen the surface and improve the adhesion of the decorative coating to the base.

First you need to clean the painted walls with sandpaper with a small grain size and degrease.

It is better to apply the impregnation with a roller, in two or three layers, following the manufacturer's recommendations.

If there are irregularities, delamination and shedding of paint on the surface, it is better to remove the old coating, re-plaster and putty.

Processing concrete and plastered walls

We impregnate concrete and plaster substrates in two approaches with a deep penetration primer, with an interval of at least 4 hours.

If the surface is too porous, peeling and crumbling, it is better to use fastening primers.

We close up defects in the base, cracks and irregularities with cement or gypsum mortar.

To ensure uniformity of color and uniformity of impregnation, we putty the walls with gypsum putty.

Apply two coats of primer evenly with a roller and brush.

You can additionally paint the walls with water-dispersion or acrylic paint.

Drywall Walls

You can apply liquid wallpaper to drywall after completing all the technological steps:

- surfaces from gypsum plasterboards are primed twice to ensure adhesion,

- close up irregularities and indentations from self-tapping screws with putty.

- glue the sheet joints with a serpentine, and then putty.

- we carry out continuous filling of the wall surface with a thin layer and allow to dry.

- We cover the base with two to three layers of primer. In this case, the next layer is applied after the previous one has completely dried.

Wood walls

When preparing wooden structures, it is necessary to take into account the high absorbency of the tree, the tendency to deformation and damage by pests, fungi and mold.

Acrylic primers of deep penetration, safe for health, are suitable for priming wooden walls indoors. They reduce the water absorption of the surface, strengthen the wood and prevent its swelling.

We choose primers containing antiseptics, fungicides and insecticides, or pre-impregnate the walls with antiseptic compounds.

We cover the walls with a primer for 2-3 times, observing technological breaks for drying the previous layers and the recommendations of the manufacturers.

For applying impregnation to wooden substrates, a roller, brush or spray gun is suitable.

Using our advice, you can easily independently prepare the walls or ceilings of your apartment for applying liquid wallpaper.

Shortly about liquid wallpaper

Liquid wallpaper is sometimes referred to as "silk plaster", one of the brands instilled this name - Silk Plaster. This finish has many advantages, but it is not without drawbacks, among which are sensitivity to substances actively interacting with water in the thickness of the wall and water solubility. The latter is eliminated by applying colorless varnish to the wallpaper.

To prevent peeling of the material, various options are used, for example, a primer from PVA or other home-made compounds. But, if you weigh the pros and cons, it turns out that using a professional primer mixture is not a waste of money, but a reasonable saving in the long run.

Why prepare the walls?

Despite the fact that you can cover almost any surface with liquid wallpaper (they go well), there are objective reasons to prepare for the repair with all thoroughness. The remains of old wallpaper, unwanted roughness, the original color of the walls - all this will immediately manifest itself after applying liquid wallpaper.

The primer is needed to hide small flaws like cracks, chips that will be eliminated by the finish layer, but the material consumption will increase, and the behavior of the crack in the future is difficult to predict.

The ability of the basecoat to absorb moisture also matters: applying wallpaper to a well-absorbing surface is associated with certain difficulties and an additional waste of the finish composition.

How will primer walls for liquid wallpaper? You can list the following positive points:

- ensuring good adhesion of the coating to the wall (adhesion),

- saving liquid wallpaper consumption,

- protection of walls against the appearance of fungus and mold,

- increase in strength and durability of the coating and base,

- protection of walls against excess moisture,

- ensuring uniformity and color matching applied liquid wallpaper expectations.

Ready-made primer for liquid wallpaper will save you from unnecessary thought about the features of combining the components of the mixture with each other and the search for additional tools and containers.

On the video: features of liquid wallpaper and work with them.

General information about liquid wallpaper

Liquid wallpaper is more a decorative coating technology. In terms of quality, this material is more related to the variety of decorative plaster than to wallpaper materials in the classical sense.They are a mixture of cellulose and silk fibers, as well as various decorative fillers (dyes, structural particles).

To turn a dry mixture into a liquid (hence the name), traditional wallpaper glue is used. But such wallpapers are applied in a slightly different way: the mass is rubbed on the surface of the walls with a trowel, as if plastering.

The biggest advantage of this type of decorative coating is the ability to use on any plane. Interior designers prefer liquid wallpaper because of the wide range of tinting possibilities.

Clients choose this modern material because it is not inferior in quality to traditional wallpaper materials: the surface of the walls is warm and soft to the touch. Perhaps the only drawback to this type of finish is the cost of materials.

Primer selection

The primer under the wallpaper is needed not only for high-quality adhesion (adhesion) of the coating and base. First of all, its task is to prevent the penetration of moisture. It is necessary to use the material where “high hydrophobicity” is indicated in the operational characteristics. It is recommended to process in 2-3 layers.

So that the protective coating does not lose its properties, each subsequent layer is applied only after the previous one has completely dried.

Under liquid wallpaper, the following primers are mainly used:

- Acrylic is the best option. Differs in easy drawing, fast drying, uniformity of a layer.

- Deeply penetrating - it is well absorbed into the base, after drying it forms a strong moisture-proof film. One of the advantages is the ability to smooth out imperfections in the base (pores, bumps).

- Quartz - are made using quartz dust. Give the treated surface a slight roughness, which in turn contributes to a better quality application of liquid decorative coatings.

Advantages and disadvantages

Liquid wallpaper has long ceased to be an exclusive decorative material. Ready-to-use mixes can be bought at any hardware store. It is enough to dilute them with water in accordance with the instructions and you can start finishing. It may seem to some that working with roll materials is much easier. However, liquid wallpaper has such a list of advantages that you can forget about some of the inconvenience.

- seamless application technology allows you not to think about combining the elements of the picture on adjacent paintings,

- Before applying, you can not align the walls too carefully. The layer thickness is sufficient to hide minor irregularities,

- liquid wallpaper is so elastic that it does not crack during shrinkage, which is inevitable in new homes,

- this material provides high sound and heat insulation,

- using several shades of liquid wallpaper, you can make decorative wall decoration in the form of an exclusive panel,

- after completion of the work, almost no waste remains.

The disadvantages include the following points:

- the porosity of the texture increases the drying time of the coating up to 48 hours,

- due to its high hygroscopicity, the material is not recommended for use in rooms with high humidity.

In order to save material consumption and increase the service life of the decorative coating, it is recommended to apply it on a primed base.

Types of compounds

Today in the market of finishing materials offer several types of primers.

- Universal, on an acrylic basis - Quick-drying coating. Easy to apply to the surface, non-toxic. Suitable for all kinds of substrates.

- Alkyd - Used exclusively for the treatment of wooden walls. Drying time 15 hours. Use for gypsum and plastered surfaces is impractical.

- Acrylic deep penetration primer - Often made with tinting and can be used as an intermediate coating layer. Deeply penetrating and well absorbing mixture. It is used for plastered and drywall surfaces. Strengthens obsolete, loose and porous, highly absorbent walls. It can be used in wet conditions.

- Water repellents - Organic binders that create a protective film. Available in the form of concentrates, which must be diluted in accordance with the manufacturer's instructions.

- Deep penetrating quartz mixture Concrete Contact - Designed for processing all types of surfaces. Fine quartz filler allows you to create a rough base for applying any finishing materials, including liquid wallpaper.

Important. Before processing, the surface must be cleaned of dust and mechanical impurities. Oil stains and islands of corrosion can subsequently appear through the coating and spoil the appearance of the finish.

One of the features of choosing a primer is the need to focus on the color of the composition. It is not recommended to strengthen the base with tinted compositions, especially if the color of the liquid wallpaper is light. The best option for preparing the walls are transparent or white compositions.

A white primer is ideal. With its help, you can achieve uniform color of the walls, and immediately visible area that has already been processed. Its use is especially relevant on a dark concrete base.

When buying, you need to pay attention to the purity of the color (the composition should be transparent or white without impurities) and the expiration date. An expired primer will not provide sufficient adhesion.

For treating concrete walls for painting or applying liquid wallpaper, there is another alternative surface preparation.

Instead of primers for liquid wallpaper, you can use PVA glue. To obtain the composition of the correct consistency, it is diluted with water in the proportion of 1/2 or acrylic paint, in the ratio of 1/3. This budget option has its drawbacks:

- does not increase the strength of the base, because it cannot penetrate deep into the base,

- does not protect against mold and mildew,

- changes color and texture over time,

- may peel off under the weight of the decorative coating.

Since liquid wallpapers are expensive finishing materials, saving on the primer does not make sense.

Concrete and plastered

A feature of concrete and plaster substrates is their increased hygroscopicity. The processing of such walls for applying liquid wallpaper takes place in several stages:

- Substrate treatment with deep penetrating compounds:

- Putty and surface leveling.

- Coating with additional primer coatings.

- Wall coating with water dispersion or oil paint.

Only after the final coating has completely dried up can liquid materials be applied.

Drywall

Unlike porous and not always smooth concrete walls, drywall sheets have a smooth surface, the processing of which takes much less time, but has its own characteristics:

- Before applying the primer, the joints of the material sheets and the recesses left when tightening the screws should be thoroughly puttyed. To ensure uniform color of the finishing material, it is recommended to putty the entire wall.

- To process walls with 2-3 layers of deeply penetrating primer.

- The metal fasteners protruding above the base must be painted over with any waterproof coating.

Wood base

Moisture negatively affects the tree. Under its influence, it begins to swell and rot, so the walls of this material require more thorough processing:

- The entire area of the wooden base is covered with special antiseptic impregnations.

- The surface is primed in several layers. In this case, it is necessary to choose compositions intended for the processing of wood.

- At the end, it is necessary to cover the base for liquid wallpaper with water-dispersion paint.

Finishing work can only be done after the last protective layer has completely dried.

Primer preparation

Before applying the primer, it is necessary to pre-treat the surface. Preparation of the base takes place in two stages:

- Stripping. At this stage, the walls are cleaned of the remnants of the old finish (pieces of plaster, putty, wallpaper and other). If this is not done, during operation they can peel off along with pieces of liquid wallpaper. Also, rust and oil stains must be removed from the surface.

- Surface alignment. It is necessary to fill all cracks, dents and chips. The decorative coating layer can only correct minor differences in wall level and microcracks.

Tools and instructions

To properly process the base, you need to prepare tools for work and get acquainted with the procedure for the work.

To apply the composition you will need:

- paint roller (preferably polyamide with short or medium pile),

- medium-sized flat brush. A synthetic fiber tool is recommended. It climbs less and is more durable,

- a primer dilution bath,

- gloves.

The procedure for surface treatment is as follows:

- the finished composition is poured into a prepared container, the dry mixture is poured and diluted in accordance with the manufacturer's instructions,

- the roller is impregnated with a solution, squeezed slightly and begin to roll on the surface, making sure that the primer does not spread, but is absorbed,

- for processing corners and hard to reach places it is recommended to use a brush

- Smooth walls that poorly absorb the composition must be rolled several times in the same place. When moving to the next section, re-wet the roller,

- After finishing work, the roller and brush must be thoroughly washed. If you do not do this right away, the composition will freeze and the tool will have to be thrown away.

Important. Application of the second layer should be done only after the first has completely dried. You can understand that the primer is frozen by touch. Fingers do not stick to a dry surface.

Common mistakes and their consequences

The process of applying liquid wallpaper to walls requires attention and patience. Hurry and violation of technologies for working with this material can be expensive. Most beginners make the following mistakes:

- It is believed that a well-painted glossy base does not require additional processing. Result: poor grip.

- Add too much water. Result: the composition turns out to be excessively liquid and not elastic, so it must be applied with a thicker layer.

- Smooth but roughened walls are not treated with soil. Result: a surface with increased hygroscopicity absorbs moisture from the decorative coating.

All these errors lead to a large overspending of the material, which significantly increases the cost of finishing work, because liquid wallpaper is not cheap.