Hello everyone DRIVE2!

Today I finished painting the plastic parts of the engine compartment.

The fact is that I wanted to wash the plastic under the hood before repair, but it turned out that there was dirt, oil stains, and so on. to such an extent that they didn’t get off with a simple sink, so it was decided to repaint the plastic in body color.

Below I will briefly describe the process itself:

1. After you have decided on the parts that will be repainted, remove them and roughly estimate the amount of work. In the future, this information will be useful in a paint shop.

2. For work you will need:

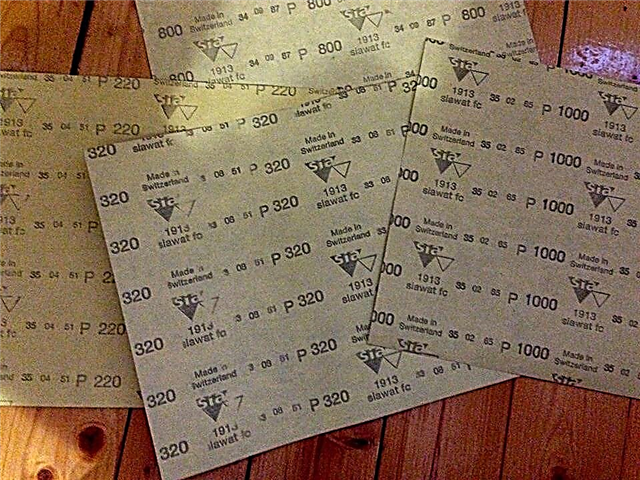

- sandpaper with grit size 220, 320, 800 and 1000,

- degreaser

- soil (consumption of approximately 1.5 m2 with application in 2 layers),

- paint (consumption of approximately 2 m2 with application in 2 layers),

- varnish (consumption of approximately 3 m2 with application in 2 layers).

3. After all the parts have been dismantled, the painting materials have been purchased, it is necessary to wash all parts as much as possible from dust and dirt.

Features

Typically, plastic products are painted at the production stage, but sometimes it may be necessary to repaint the product (or part of it) in a different color in order to change its appearance or restore the old coating. Special paints in spray cans are ideal for such purposes.

Such coloring agents are distinguished by a special composition, thanks to which they perfectly fit onto the plastic without harming it.

So that when painting the plastic, the coating does not peel off and looks no worse than the factory one, it is necessary to choose the right paint and apply it correctly.

Advantages and disadvantages

The advantages of sprays include:

- convenience and simplicity in work,

- even application

- long storage

- the richness of the color palette,

- brightness of colors

- resistance to the rays of the sun (do not fade and do not fade).

Such paint will not dry out, even if you have already used the spray can several times. In addition, these enamels do not require the purchase of brushes or rollers for application. Consumption is quite economical - one cylinder is enough for a long time.

The disadvantages include the impossibility of self-calling. Of course, a painter in the store can create any complex color for you upon request, but this will require additional costs.

It is also quite difficult for beginners to work with aerosols: paint may form smudges, apply unevenly.

If it is necessary to paint a small portion of the surface, then the entire remaining area must be covered with masking tape so as not to apply paint from a spray bottle on it.

Polymer

Combine at once two functions: a primer and coloring. They have a higher level of adhesion, so they do not require preliminary priming of the surface.

With acrylates and / or polyurethane additives

More durable, damage-resistant compounds that are used to cover surfaces subject to shock and abrasion.

Structural

When such a paint dries, the surface becomes rough, hiding small defects in the material. Allows you to create a design more original than intended by the manufacturer.

Monad

Such paints are used on PVC plastic. They are waterproof, adhere well to the surface, and are also protected from ultraviolet radiation.

Areas of use

Aerosol for plastic is used in the restoration of those products that have lost their original appearance, as well as to give them additional strength and moisture resistance. This paint is also used for painting cars and in interior decor..

Both professional car dealers and designers, as well as beginners, work with it, because it is very convenient.

Tools

Despite the fact that when working with aerosols, you can do without various brushes and rollers, nevertheless, for the convenience of work, you need to prepare the following:

- "Skin" of small grain,

- water, a rag and a detergent,

- masking tape, if you are not processing the whole product,

- any degreaser containing alcohol,

- primer for some types of plastic (ABS and PVC plastic),

- protective equipment: goggles, gloves and a respirator or mask.

Surface preparation process

Before proceeding directly to staining, plastic must be prepared in a certain way.

- First, the product must be cleaned with a stiff brush with detergent, then rinsed with water and allowed to dry completely.

- After that, the product is polished with a “skin”, smoothing out all the bumps. If the defects are too deep, you can use a special primer for plastic and smooth the surface.

- Then the plastic must be treated with a degreaser, and then you can start the primer if it is necessary for this type of material.

- If in doubt about the type of material, it is better to put a primer in any case. It will not be superfluous, but it will provide a more reliable adhesion of the paint and the surface of the plastic.

See how to properly prepare plastic for painting in the next video.

Painting

Spray painting takes place in several stages:

- First, with cardboard, film or an unnecessary piece of cloth, it is necessary to close all areas not intended for painting. Very small areas can be sealed with tape (use masking tape, since regular tape can damage the old coating when it is removed). If the product is small, it is advisable to lay it horizontally on any surface over which the paint will be sprayed.

- Shake the paint cylinder for 30-40 seconds so that the dye is evenly mixed.

- Remove the cap from the spray gun at the top of the bottle. Apply paint on the plastic with constant smooth movements, without holding your hand in one place to avoid drips.

If you are using a new bottle, it is advisable to check the color and consistency of the dye on a separate piece of cardboard or on the side of the product that is least visible. Also, for the first seconds, paint from the balloon may come out in jerks. Do not begin to paint the surface until the spray becomes even and wide.

- The hand with the spray can be kept at a distance of not less than, but not more than 20-30 cm from the surface to be painted.

- After applying the first coat, let the paint dry for 30-40 minutes. Then you can apply a second coat and also let it dry. If necessary, it is permissible to apply additional layers according to the same algorithm.

- Despite the fact that the paint itself dries quickly enough, it is not recommended to use the painted product within one day. During this time, the coloring matter is finally polymerized, so the surface will be reliably protected from various damage.

Getting a mirror coating

To achieve the effect of silver or gold-colored metal polished to a shine, the plastic is coated with a special paint, and the process itself is called chrome plating.

The price for this service is quite high, so independent work with such a dye is a great opportunity to save.

In general, the process of working with chrome paint is carried out in the same way as with any mixture for plastic in a cylinder, only a spray is applied to the surface already pre-painted with black paint. Without preparatory coloring in black color, creating a mirror effect at home simply will not work.

There are several more subtleties of staining with chrome:

- It is better not to chase the cheapness and purchase proven compounds from foreign manufacturers.

- It is more difficult to apply such an aerosol than regular paint, so it is worth pre-training on various surfaces and areas.

- If the product will be varnished, you must first check the compatibility of the purchased paint and varnish. Some types of varnish mixtures can destroy even a correctly applied layer of chromium.

It is necessary to be prepared for the fact that balloon paint and chrome plating with your own hands do not always give the effect of salon staining, but the prospects for development in this direction are quite high.

Characteristics of dyes for plastic surfaces

Aerosol sprays for painting plastic are popular with most decorators because of their ease of use. The following enamel types are available in spray cans:

- Polymeric, combining the functions of a primer and a dye. Polymer paints for plastic are highly adhesive and do not need a preliminary primer.

- Resistant to damage. These are especially strong compounds, in the manufacture of which polyurethane additives and acrylates are used. This type of enamel is used for surfaces exposed to great mechanical stress.

- Structural. Such dyes, when dried, give a beautiful, slightly rough surface, hiding small flaws that have arisen on plastic. The use of structural paints allows you to create original decor.

- Soft touch A coloring composition that allows you to get a velvety to the touch surface. Items decorated with this kind of enamel create a feeling of softness and comfort.

- Monad designed for PVC plastic. It adheres well to the base, UV resistant.

Such a wide range of compositions for painting allows you to choose an aerosol preparation suitable for a certain type of plastic.

Preparation for painting

For beginners, the process of working with an aerosol dispenser may seem complicated, but the exact observance of all stages will help to achieve success. Before you start painting, you must prepare the surface of the product. To do this, do the following:

- Product cleaning. In order for the final result to please with beauty and durability, it is necessary to thoroughly rinse the surface with water with the addition of detergent, deep contaminants can be washed with a hard brush. Do not be afraid to scratch the surface of the plastic: further grinding and applying enamel will make the surface smooth. But if the dirt is not completely removed, then the paint will lie unevenly and will soon begin to bubble or crack. After the item is washed, it must be rinsed with clean water to remove residual detergents and dried well.

- Grinding. All small irregularities are smoothed out using a fine-grained skin. If the product has large cracks or dents, then before grinding them it is recommended to smooth them using putty for plastic.

- Degreasing. Various grease stains worsen the adhesion of the enamel to the base, therefore it is necessary to remove them using degreasing agents. It is not necessary to rinse alcohol-containing degreasers, but other solvents must be removed by washing the product with clean water, and dried.

- Padding. This step is not required for all types of plastic. How to determine the need for priming? Put the plastic thing in a large container of water: if it drowned, then the application of the primer can be skipped. In case there is doubt about the need for a primer, it is better to apply the primer. Additional priming will contribute to more durable adhesion of the enamel to the base.

After the soil has dried, you can start applying the paint.

How to work with a dye bottle

Paints in aerosol cans, when sprayed, form a fine suspension in the air, which settles not only on the object to be painted, but on other surfaces. In addition, small particles of paint can get into the eyes or the respiratory tract. To avoid this, do the following:

- Covering material (for this purpose you can use plastic wrap, cardboard, old cloth, etc.) to cover all areas not intended for painting. Tap bottlenecks that do not need to be painted with masking tape.

- Wear protective glasses, a respirator and gloves during operation.

After such preparation, you can paint. You need to do this as follows:

- If the item to be painted has a small size, then to improve the quality of the painting it is better to place it on a horizontal surface laid with covering material.

- Shake the enamel can for 30-40 seconds to mix the dye.

- Remove the cap and first, test, a stream of paint to release on an unnecessary basis, for example, on a piece of cardboard. This is necessary because air can accumulate in the atomizer and the first pieces of enamel will fly out with uneven “spitting”. After the dye begins to exit the cylinder evenly, you can begin to paint the plastic.

- When spraying, move the hand with the aerosol in smooth movements, not lingering in one place. Long spraying of one area leads to the formation of streaks of enamel. Keep the aerosol at a distance of 20-30 cm from the surface to be painted.

- After staining, allow the first layer to dry (approximately 20-30 minutes) and repaint. If necessary, apply the third and subsequent layers.

Despite the fact that the coloring solutions for plastic dry quickly, it is recommended to start using the product only after a day. During this time, the final polymerization of the coloring agent will occur, and the decorative layer will become durable.

Useful Tricks

To make the painting quality, professional masters recommend:

- Acquire cylinders with interchangeable tips, making it possible to adjust the width of the jet of the coloring matter.

- Apply a new layer only after the previous one dries.

- If the product is supposed to be used frequently, it is recommended to apply more layers.

Observance of these little tricks and strict adherence to all stages of painting guarantees an excellent result.

It is very convenient to use aerosols for painting plastic products. If you choose the type of coloring matter in accordance with the purpose of the thing and the type of plastic, then the decorated item will delight for a long time with its beautiful appearance.

The nuances of the selection of paint in spray cans

First of all, you need to know what kind of plastic your parts are made of, since the further choice of the properties of the dye and the technology of its application depends on the material itself.

- ABS (Acrylonitrile Butadiene Styrene) - Housings of household and computer equipment, mobile phones and much more are made from it.

- PVC (Polyvinyl Chloride) - window structures, floor coverings, children's toys and goods, some types of household containers.

These two types of plastics differ in that when they are painted, a prerequisite is the application of a primer. Its presence gives high-quality adhesion of the paint to the surface, which eliminates subsequent detachments and cracks. If you do not have information about what type of plastic you have in your hands, there is a simple method to check.

Fill a container with water where your plastic part will fit (except for bulky items). Dip the item in water. If the plastic is sinking, then a primer is not required. You can apply the paint directly to the surface. If your part remains afloat, you must purchase a primer spray. Without it, the paint will not last long.

Pros and Cons of Aerosol Enamel

Spray paints are easy to use. You do not need special skills, training or additional expensive equipment. It is enough to adhere to simple recommendations from the manufacturer.

The advantages of enamel also include:

- Smooth smooth surface. Modern heads for spray cans are made in such a way as to simulate the torch of a paint spray gun. This allows you to achieve uniform spraying of enamel, so that you get an even, smooth surface layer.

- Drying speed. Spray paint dries very quickly, which is an undoubted convenience, because you do not have to spend a lot of time working and speed up drying by additional methods.

- Cost-effective consumption. Balloon enamel is consumed slowly and one spray is enough for a large surface.

- Convenience of storage. There is no need to create special conditions for storing unused residues, to overfill and carefully close, as is the case with can paint. Enamel in a cylinder is stored very long and reliably.

- A large palette of colors and structures. This allows you to achieve great artistic expression and imitate many surfaces, for example, for metal.

However, the coating surface using a spray is small. It is not possible to mix paints to obtain the desired shade. As a rule, there is a certain set of colors for sale, so it’s not always possible to get exactly the tone of the wallpaper or window details.

Complex shades and in the right amount can be ordered at the color matching laboratories, but it will cost significantly more.

Cons of spray paint:

- If the aerosol is brought too close to the surface to be painted, smudges may form on smooth plastic. To work with spray cans, you need to acquire skills and dexterity.

- Large spray area. Elements for painting will either have to be dismantled or protected against splashes with the help of a film and special, paper tape adjacent surfaces.

- Limited ink density. You will not be able to adjust the degree of opacity or transparency of the paint, you will have to work with the degree of enamel density that is provided by the manufacturer.

- The temperature regime of the work. The coloring of the external elements must be carried out in warm, calm, sunny weather. In the event of wind or precipitation, the result is unpredictable.

- Some paints may contain acetone and its derivatives. Be sure to study the composition and consult on this issue with the seller. Acetone enamels can seriously damage plastic.

Types of paints for plastic

- Polymer. Basically, this is a high-gloss paint that combines both the properties of paint and soil. In addition, this enamel does not require the application of a varnish layer, it itself gives a high level of gloss on the surface. Polymer paints are both permeable and waterproof.

- Polyurethane This enamel based on polyurethane resins has high wear resistance, strength and excellent gloss. The composition allows you to create a durable coating that is not afraid of daily friction, small impacts and sharp objects. This paint provides for the use of a primer material and is suitable exclusively for application to stiff parts, as the paint layer has a significantly higher strength than plastic. Detachable parts are inevitable on soft, flexible plastic.

- Structural. This paint contains special particles that create a textured surface resembling semolina with a different grain size. This property will successfully help to hide any imperfections in plastic.

- SoftTouch (SoftTouch). Paint allows you to create a pleasant velvety or velor surface. This type of coloring gives the product an expensive appearance and a pleasant to the touch texture.

Automotive paints and their features

To paint plastic with your own hands, you can use specialized automotive paints and primers.

- Base for varnish. This type of enamel must be applied to a special primer on plastic, which will increase its adhesion to the surface of the part. Finally, the area to be painted must be spray-coated. Basic enamel can be in simple colors, as well as with the effect of metallic and mother of pearl, which allows you to transform home decoration.

The paint has a rich assortment of colors, including options for “gold” or “silver”, with different grain sizes - from very small to large, with bright sparkling flakes.

- Enamel with chrome effect. Allows you to create a surface similar in appearance to chrome. The effect of a well-polished mirror captivates with its beauty and looks expensive, however, it will not hit the budget.

- Paint with the effect of aluminum. The enamel has a fine and dense grinding of the dye, so that the effect of the reverse side of aluminum foil is created on the surface. There is no mirror shine, but there is a soft, delicate glow.

Along with the base for varnish, paints with various effects are made in gold, platinum, antique silver or copper. They have the finest grinding of the dye, due to which a reliable imitation of the precious metal is created.

- Vinyl paints. If you are a lover of interior decoration under the skin, then this paint is your option. Any plastic surface painted with vinyl enamel, externally and to the touch will be as similar as possible to leather products. The advantage of this paint is plasticity and an increased level of adhesion, which eliminates the primer. You can not be afraid of cracks and chips, this is possible.

- High temperature enamels. Of course, interior items can hardly be heated to temperatures that this enamel is able to withstand. But if you want to repaint or renew the surface of an electric kettle, vacuum cleaner, plastic parts of a coffee machine that are heated in one way or another, then high-temperature paints will come to your aid.

Before painting parts, you must:

- to clean the plastic surface with sandpaper with abrasiveness of the order of 1500-200 grit,

- degrease the place of intended enamel application with an alcohol cleaner using a lint-free cloth,

- Before painting the main part, you should practice on an unnecessary piece of plastic: determine the pressure on the spray head and select the optimal distance from the spray can to the surface.

You will learn how to paint the plastic yourself with a spray can from the next video.