If you first went to the store to buy cement glue, then you probably faced difficulty in choosing. Almost every hardware store has dry mix Ceresit from the German manufacturer Henkel. They are made at a Russian factory. From this material you will learn the technical characteristics and purpose of each type of Ceresite glue.

The information is taken from the official website of the manufacturer, and the specified characteristics are correct in conditions of temperature +20 degrees and humidity 60%.

Quick article navigation

Ceresit CM 9

SM 9 glue is the weakest among all Ceresitov cement-based options. It is moisture resistant, but it has reduced indicators of frost resistance, adhesion and the life time of the solution, freezes 2 times longer. It can be used for laying glazed tiles and terracottas up to 30x30 cm in size on a concrete base on the floor and walls inside buildings. It can also be used for masonry.

Specifications

| Mixing ratio | 5 liters of water per bag 25 kg. |

| Mixing time after mixing | 2 hours minimum |

| Conditions of use | Base and air temperature from +5 to +30, air humidity less than 80% |

| Open hours | From 10 minutes |

| Tile Correction Time | From 15 minutes |

| Tile sliding | No more than 0.5 mm |

| Grouting | After 48 hours |

| Adhesion to concrete after 28 days | More than 0.5 MPa |

| Frost resistance | Not less than 50 cycles |

| Operating temperature | Up to +50 |

| Packaging | 25 kg bag |

Consumption

| Tile length, cm | Comb tooth height, mm | Consumption, kg / m² |

|---|---|---|

| Ceresit CM 11 Plus |

The most popular tile adhesive from Ceresite is CM 11. It is suitable for gluing tiles on the street and indoors, as well as porcelain stoneware (only inside). Not afraid of frost and moisture.

The tile must have a water absorption of more than 3% (or porcelain tiles

Technical characteristics Ceresit SM 11:

| Mixing ratio | 6 liters of water per 25 kg of dry mix (approximately 1 to 4). If an elasticizer is added: 4 liters of CC 83, 2 liters of water, 25 kg of dry mix. |

| Mixing time after mixing | 1.5-2 hours |

| Conditions of use | Base and air temperature from +5 to +30, air humidity less than 80% |

| Open hours | From 15-20 minutes |

| Tile Correction Time | 25-25 minutes |

| Tile sliding | No more than 0.5 mm |

| Grouting | After 24 (72 *) hours |

| Adhesion to concrete after 28 days | More than 0.8 (1.3 *) MPa |

| Frost resistance | No less than 100 cycles |

| Operating temperature | From −50 to +70 |

| Flammability according to GOST 30244—94 | NG (non-combustible material) |

| Packaging | Bags 5 and 25 kg |

* The asterisk indicates the characteristics when adding an elasticizer.

Scope and variety of glues

Ceresit dry mixes are manufactured by Henkel and are used for exterior and interior use, for walls and floors, and various types of substrates. The range of tile adhesives is huge, there are universal and specialized tools on sale. All Ceresit compositions vary in scope, and for the convenience of determining the destination have the following markings:

- SM - building mixtures for fixing ceramic tiles,

- CB - adhesives for fragmentary repair of lined surfaces,

- ST - mixes for installation of external (front) thermal insulation.

The purpose of the funds is different, the user can always find the right solution. Standard adhesives of the SM brand have high adhesion with brick, concrete, and are used for laying tiles, mosaics, porcelain tiles indoors and outdoors (for example, “Cerezit SM 110”). Some adhesives due to moisture resistance can be used in the bathroom, other wet rooms. Elastic adhesives will help to fix the finishing material on surfaces prone to vibration, shrinkage. There are also special adhesives of the SM series for:

- large-format floor tiles,

- mosaics and marbles (white glues),

- clinker

- front tile.

The CT line includes ready-made products and dry mixes for breeding for outdoor use. The most popular among builders are such compositions:

- CT 84 polyurethane adhesive for expanded polystyrene (used in the installation of external thermal insulation of facades),

- CT 190 stucco-adhesive mixture (CT190 is used for the installation of mineral wool boards and the base plaster layer for facade insulation),

- CT 85 stucco mixture for polystyrene boards (for indoor and outdoor use).

In the series CB 10-100, acrylic and other mounting adhesives in cylinders are produced, with which they work indoors and outdoors. All of these Ceresit adhesives can be fixed only with tiles and heat-insulating materials, and for laying other coatings it is necessary to choose specialized compounds (for example, UK 400 for PVC and linoleum). Each glue has a certificate of conformity, confirming its high quality.

Ceresit CM 11 Plus

The composition of Ceresit CM 11 Plus is considered a classic, it is most often used for laying tiles, porcelain stoneware in exterior and interior works. Glue includes a number of minerals and modifying additives, which provide a high degree of adhesion to various non-deformable substrates:

- concrete

- cement coatings

- cement-lime screeds,

- brickwork, etc.

CM 11 glue is suitable for stickers of any type of tile, except marble, measuring less than 50 * 50 cm on the floor and walls outside, inside buildings. It can also be used for laying porcelain stoneware for interior use. When adding special CC 83 elasticizer, the tool can be used for installation of waterproofing coatings, underfloor heating, plinths, exterior stairs and various deformable substrates - drywall, chipboard. In addition, the introduction of an elasticizer improves the properties of the adhesive and its use for gypsum, aerated concrete, paint coatings.

The characteristics of CM11 glue are as follows:

- consumption of 1 m2 - 1.7-55 kg / sq. m (depending on the size of the tile, trowel teeth),

- the viability of the solution is 2 hours,

- adjustment time - 20 minutes,

- the readiness of the tile for grouting - 72 hours,

- tile sliding - up to 0.5 mm,

- adhesion - 1 MPa,

- the temperature of application of the solution is + 5 ... + 30 degrees, operation - -50 ... + 70 degrees.

The glue is frost-resistant - it easily withstands 100 cycles of freezing / thawing. Also, the product is considered waterproof and can be applied to the walls, the bottom of the pools (after the introduction of an elasticizer).

Ceresit CM 12

Glue "Ceresit SM 12 Porcelain tile" is a specialized composition for fixing large-format floor tiles. It reliably holds slabs up to 60 * 60 cm in size, while it is suitable only for non-deformable substrates - concrete, cement screed. In humid areas, the composition can be applied in conjunction with waterproofing CR 65. The product has a plastic texture, prevents the appearance of voids under the tiles, has a high degree of adhesion to the base. CM12 glue is suitable only for internal work.

After the introduction of the CC83 elasticizer, the field of operation of the composition is expanding significantly. It can be applied on such surfaces:

- heated screeds,

- old tile facings,

- concrete from the age of a month ("young concrete"),

- gypsum, anhydride screeds,

- OSB boards, drywall, chipboard.

The product has low frost resistance - up to -30 degrees, therefore it is not used in freezing rooms, outside buildings. Tile adjustment time when applying CM 12 is increased to 30 minutes, the pot life of the solution is 2 hours. Other characteristics:

- tile sliding - up to 0.5 mm,

- the period before grouting - 48 hours,

- adhesion - 1 MPa.

The material flow calculator also depends on the size of the boards. If the size of individual elements does not exceed 30 * 30 cm, about 4.2 kg / sq. Is spent. m of glue. On laying tiles 60 * 60 cm, about 6 kg of mixture / sq. m

Ceresit CM 14 Extra

The product marked “Extra” - is frost-resistant, moisture-resistant, does not allow tiles to slide, perfectly combined with underfloor heating systems and waterproofing. Glue is suitable for external, internal works. Special fibers give the composition greater strength and elasticity, reinforcing mesh increases the impact resistance of masonry. The scope of CM 14 is as follows:

- all types of ceramic tiles,

- slabs of artificial, natural stones,

- porcelain tile

- cement based materials.

The glue is intended for non-deformable bases made of cement, concrete, it can be used in the bathroom and other wet rooms. How much does the material dry? The time to grout the tiles is only 24 hours. Other characteristics of "Ceresit SM 14":

- the pot life of the solution is 2 hours,

- temperature during work - + 5 ... + 30 degrees,

- adjustment time - 20 minutes,

- adhesion - 0.8 MPa,

- frost resistance - 100 cycles,

- operating temperatures - -30 ... + 70 degrees.

The material consumption is equal to 2.7-6 kg / sq. m, the first digit is for tiles smaller than 15 cm, the second for more than 45 cm.

Ceresit CM16 Flex

Glue "Ceresite SM 16" is also reinforced with Fiber Force microfibers, has increased elasticity, can be used for all types of tiles. It is resistant to deformation, therefore it is suitable for such bases as gypsum fiber, drywall, fiberboard, chipboard, OSB-plate. The building mix is combined with waterproofing materials, it is waterproof, frost-resistant, suitable for balconies, terraces, indoor pools. It can also be used for the installation of heated screeds, overlaid on top of the old tiled cladding.

The elasticity of the glue prevents the appearance of shearing stresses during deformations. The tool is characterized by increased open time - up to 25 minutes, the same amount is a possible period for adjusting the position of the elements. Parameters "Ceresite CM16":

- tile sliding - up to 0.5 mm,

- the possibility of grouting - after 24 hours,

- adhesion - 1 MPa,

- frost resistance - 100 cycles,

- consumption - 2-4.2 kg / sq. m

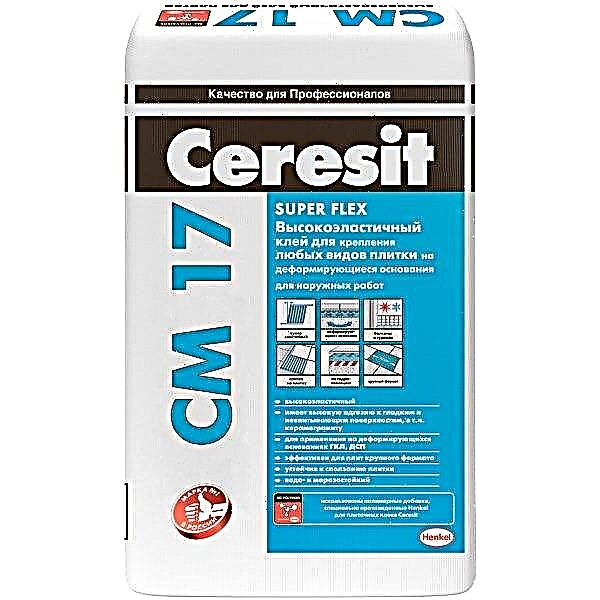

Ceresit CM 17

The superelastic glue “Ceresit SM 17” is a tool reinforced with Fiber Force microfibres and designed for all types of tiles. This dry building mix is the most resistant to deformation, has a high level of adhesion, and does not allow tiles to slide. CM17 glue is characterized by frost resistance, moisture resistance, suitable for facing the outer part of stoves, fireplaces, hamams that do not heat up more than +80 degrees. Features and technical parameters of glue:

- can be used on particleboard, drywall,

- suitable for indoor and outdoor use,

- compatible with waterproofing "Ceresit" CR 65-166, CL 51,

- suitable for heated screeds, pools,

- not used on marble,

- the density of the dry mixture is 1.25 kg / cubic dm, of the finished solution - 1.45 kg / cu. dm

- adjustment time - 30 minutes,

- consumption time - 2 hours,

- tile sliding - less than 0.5 mm,

- the possibility of grouting - after 24 hours,

- adhesion - 1.3 MPa,

- operating temperatures - -50 ... + 80 degrees,

- frost resistance - 100 cycles.

“Cerezit SM 17” is produced in two versions: glue with standard and low dusting.

Ceresit CM 115

Glue for mosaics and marbles of the brand “Ceresite CM 115” has a white color, therefore it is perfect for all types of marble, different types of stone, light limestone, transparent mosaics, and glass plates. Such materials are attached to non-deformable substrates: aged concrete, cement plasters, etc. Work with glue can be carried out outdoors and indoors. The advantages of the tool are as follows:

- frost resistance, moisture resistance,

- tile sliding resistance (up to 0.5 mm),

- suitability for heated screeds, rooms with constant humidity, balconies, terraces, pools, tanks,

- environmental Safety,

- lack of spots, fading on marble,

- the ability to stick tiles on any deformable materials after adding an elasticizer,

- compatibility with waterproofing.

They work with this glue at temperatures of + 5 ... + 30 degrees, coating operation is possible at -50 ... + 70 °. The adhesion of the composition is 0.8 MPa, the correction time of the tile is 25 minutes, the glue's pot life is 2 hours, and frost resistance is 100 cycles.

Ceresit CM 117

Glue "Ceresit SM 117" - a specialized tool for facade stone, clinker tiles. This building mixture is elastic, can withstand moisture and frost, has a good degree of adhesion. Adhesive is used inside and outside the premises, for the installation of underfloor heating. Using CM117, you can glue all types of mineral tiles, except marble, on non-deformable substrates. Most often, glue is used for decoration:

- balconies

- terraces

- indoor pools

- socles

- parapets

- old tile coverings,

- acrylic oil coatings,

- cellular and "young" concrete.

Deformable substrates can be finished with such glue after the introduction of elasticizers. The viability of the solution is 2 hours, the adjustment time is 15 minutes. Sliding tiles takes place no more than 0.5 mm, adhesion is 1 MPa, frost resistance - 100 cycles. During operation, the product withstands temperatures of -50 ... + 70 degrees.

Preparation of the base and instructions for use

To tile reliably held on the surface, you need to provide it with optimal bearing capacity. It is important to remove all fragile areas, sand, completely clean from traces of paint and plaster. Then the irregularities must be leveled with plaster, let it dry completely before gluing the tiles (usually the process takes 3 days). The floors are leveled with a suitable floor mortar.

Also, all contaminants that potentially reduce the adhesion of the composition should be removed from the base:

If the floor is cement screed, wait at least 28 days to reach a moisture content of 4%. Only then is the primer and tile laid. The bases from a tree are primed by special means for 1-2 times. Do the same with various plates, drywall. OSB boards, paint coatings are treated with rough sandpaper and dust free.

The norms for diluting glue and adding an elasticizer are indicated on the packaging, they must always be observed exactly depending on the type of glue “Cerezit”. Pour clean cold water into a bucket, pour the building mixture, mix with a mixer, a drill with a nozzle. After withstand a technological pause (7 minutes), allowing the mixture to mature. Then the mass is re-kneaded and used for its intended purpose.

To apply glue, use a notched trowel or a grater with square teeth. Trowel glue, put on the base, level with a spatula. Press the tile as hard as possible, repeat the work further, not forgetting the inter-tile seams. Butt laying is not allowed. When installing large-format objects, stone, during facade work, glue is applied to the surface of each tile and to the base. The thickness of the adhesive joint is 3 mm, it depends on the complexity of the work and the size of the tile.

Traces of glue from the front of the tile are removed immediately with a wet rag. After hardening, you will have to do mechanical cleaning. Grouting is carried out after the time recommended by the manufacturer. Do not allow the solution to come in contact with the skin or eyes. To do this, it is important to observe preventive measures, wear gloves, protective clothing and glasses. Compliance with all the tips guarantees an excellent result when working with tiles and other types of finishing materials.

A variety of adhesives company Ceresit

The Ceresit range of tile solutions contains formulations for both indoor and outdoor use. There are universal dry mixes and specialized formulations. All of them have different uses, to determine which is enough to look at the labeling.

- SM - a dry mix for ceramic tiles. It has good adhesive properties with respect to masonry and concrete.

- SV - for repair of individual parts of the cladding.

- ST - compositions for external use, thermal insulation works.

Compositions of the SM brand are used in the installation of tiles, mosaics, kerogranite. There are varieties for indoor and outdoor use. Moisture-resistant compounds are used in rooms with high humidity. This is an elastic compound that reliably attaches the finish even in places with vibrational stress, on surfaces prone to shrinkage. The SM series includes adhesives for large tiles, marble, facade cladding and clinker.

Popular blends of the ST series:

- ST 84 - polyurethane solution with which expanded polystyrene is glued during external thermal insulation works,

- ST 190 - a stucco-adhesive agent that adheres mineral wool, is also applied as a base plaster during the insulation of facades,

- ST 85 - polystyrene boards are plastered inside and outside the building.

The CB series is represented by acrylic-based mounting adhesives on an acrylic basis. They are used inside and outside the building.

For all series only tile or insulation is glued, for other coatings or materials Henkel produces specialized compounds. Any product has a certificate of conformity, which confirms the high quality of the product.

How to breed

Each glue package has an instruction. It provides information on the preparation of the solution.

The proportion in which the building composition is combined with the liquid for each series may differ, therefore, before preparing the solution, you must carefully read the recommendations and adhere to them.

You can dilute the mixture with water or with an elastomer SS-83, which mixes with water in a ratio of 2: 1. The water temperature should be + 10 ... + 20 ° C. The adhesive is poured into the liquid and mixed thoroughly.

A construction mixer or drill with a spiral mixer is used. The tool should run at 500-800 rpm.

When the mixture acquires a uniform, viscous consistency, it is no longer mixed and left to ripen for 5-7 minutes. After, the solution is mixed again and applied as directed.

Instructions for use

For reliable adhesion of tiles to the surface, it is important to prepare the base for gluing.

- The old coating, peeling areas, traces of paints and plasters are removed. The surface is sanded, and irregularities are plastered. Wait for the time when the surface is completely dry. On average, it takes about 3 days. Before laying the tiles on the floor, it is leveled with a special building mixture.

- Dust, dirt, greasy, oil stains, bitumen are eliminated from the base. After laying the cement screed on the floor before the installation of the tile should pass at least 28 days. Screed moisture should be no more than 4%. Only after that the base is primed and the floor covering is laid.

- Wooden substrates are treated with special primers at least two times. It is also necessary to prime plasterboard surfaces. OSB boards and paint substrates are rubbed with sandpaper and then dust-free.

The adhesive is prepared immediately before installation.

It must be applied with a notched trowel or a grater with square teeth.

The mixture is filled with a trowel, laid on the base, and then leveled with a spatula. The cladding is laid on the adhesive mixture, pressed tightly to the base, and one should not forget about the formation of the inter-tile seam. Butt laying is not allowed. When bulky tiles are laid or work is carried out on the street, the adhesive mixture is applied not only to the base, but also to the tile or stone itself. The layer thickness of each glue will differ, because it depends on the series of the mixture, the size of the facing material and the complexity of the work.

If the glue gets on the front side of the tile, it is easily cleaned with a damp cloth. When the excess and stains of the mixture have solidified, they are removed mechanically.

Grouting is done after the adhesive layer has completely hardened. The period of complete solidification is individual and is indicated on the package.

When working with Ceresit mixtures, they should not be allowed to get on the skin and mucous membranes. To prevent the use of personal protective equipment and clothing.

Varieties and features of glue

Ceresit offers consumers a fairly wide range of tile adhesives, so you can choose a fixing mixture based on the nature of the work. There are several categories of material:

- standard material - without additional impurities to protect the base from moisture, external atmospheric influences and other factors,

- elastic composition - suitable for fixing all types of tiles, for working inside and outside the building,

- special products - suitable for laying marble, granite, mosaics or dimensional tiles.

Material is selected depending on the type of application. Also, the composition affects the method of dilution, flow rate and method of application.

Ceresit CM16 Flex

Heat-resistant tile adhesive has a high degree of elasticity, due to which it can be used for laying on a warm floor and other substrates subject to deformation. In addition, the material is moisture and frost resistant, easily tolerates atmospheric influences, which allows it to be used indoors and outdoors. The price for 25 kg is 670 rubles.

Ceresit CM 16 Flex 25kg

Operational time after dilution, h

Operating conditions

The temperature of the base and atmospheric air + 5-30 ° C, humidity - up to 80%

The proportions of water and products

8 liters per 25 kg dry texture

Facing adjustment time interval, min.

Sliding of the finishing material, mm

Adhesion to concrete after 28 days, MPa

Resistance to frost, cycles

The consumption of tile adhesive depends on the size of the tile and the cutouts of the comb. In this case, you should focus on the following parameters:

Lining size, mm

Comb cutout height, cm

Estimated consumption, kg / m2

Ceresit CM 12

Ceresite for a warm floor has a unique composition, thanks to which it can be used for laying tiles with sizes up to 60x60 cm. This mixture is used exclusively for interior work and for facing bases of non-deformable type. Frost resistance reaches up to -30 ° C. For laying underfloor heating in glue, it is necessary to add a special elasticizer brand CC 83.

Ceresit SM-12 25 kg

Operational time after dilution, h

The temperature of the base and atmospheric air + 5-30 ° C, humidity - up to 80%

The proportions of water and glue

6-6.30 l per 25 kg dry consistency

Facing adjustment time interval, min.

Sliding of the finishing material, mm

Adhesion to concrete after 28 days, MPa

Consumption with a tile length of up to 30 cm and a comb tooth height of 1 cm does not exceed 4.4 kg / m2, and when laying cladding up to 60 cm in size with a spatula of 1.2 cm - 6 kg. The price for a bag of 25 kg is 420 rubles.

Ceresit CM 11

This is the most common mixture that is used to fix the tiles outside and indoors. Also, the adhesive is used for laying granite, but in this case only internal use is possible. The main thing here is to follow the manufacturer's recommendations. The size of the tile should not exceed the parameter 40x40 cm, and also absorb more than 3% moisture. Can be laid on a warm floor.

Ceresite SM 11 Plus has the following features:

Working time after dilution, h

Surface and atmospheric air temperature + 5-30 ° С, humidity - up to 80%

The proportions of water and glue

6 liters per 25 kg dry texture

Facing adjustment time interval, min.

Sliding of the finishing material, mm

After a day or 72 hours in the case of using an elasticizer

Adhesion of adhesive to concrete after 28 days, MPa

Resistance to frost, cycles

Material consumption depends on four factors - tile size, height of comb scars, use of an elasticizer and the experience of the master. Tentatively, it varies from 1.7 to 4.2 kg / m2. For example, when laying tiles up to 15 cm long with a spatula with 6 mm teeth, about 2.7 kg per 1 m2 is required.

Ceresit CM 14 Extra

The material is suitable for the installation of tiles and porcelain tiles with dimensions up to 450x450 mm. Installation is allowed in normal and humid rooms on the floor or walls. Tile glue Cerezit SM 14 is applied to the base in the form of a cement or concrete screed. After dilution, the master has 2 hours to completely use up the mixture. The price for 25 kg is 450 rubles.

SM 14 Extra 25 kg

Time after dilution, h

Adhesive recommendations

The temperature of the base and atmospheric air + 5-30 ° C, humidity - up to 80%

The proportions of water and mixtures during dilution

6.25 L per 25 kg dry mix

Facing adjustment time interval, min.

Sliding finish, mm

Adhesion of adhesive to the concrete base after 28 days, MPa

Resistance to frost, cycles

Ceresit CM 9

This is the weakest and budget of all solutions, since it is made on the basis of cement. It is resistant to humid environments, but does not tolerate severe frosts. It should also be noted how much the terezit tile adhesive dries, in this case it will take 2 times more than usual. The material is recommended for use for the installation of tiles and terracotta with dimensions up to 30x30 cm. Concrete screeds and masonry can serve as the basis.

Time after dilution, h

Recommendations for use

The temperature of the base and atmospheric air + 5-30 ° C, humidity - up to 80%

The proportions of water and mixtures during dilution

5 liters per 25 kg of dry mix

Facing adjustment time interval, min.

Sliding finish, mm

Adhesion to the concrete base after 28 days, MPa

Resistance to frost, cycles

The price for a bag of Ceresite SM 9 25 kg - 250 rubles.

How to dilute tile glue and how to use

Before applying the mixture, you need to figure out how to dilute it to the required consistency. In this case, instructions from the manufacturer will help, since each brand has an individual recipe with a certain ratio of components and water. The overall process is as follows:

- divide the total mass into several equal parts, this will allow you to work without rush and worries that the process is not over yet, and the glue is already drying,

- in a clean bucket, place 2/3 of the indicated volume of water and gradually pour the powder into it, while thoroughly mixing with a construction mixer,

- Despite the manufacturer's instructions, independently evaluate the consistency condition, it should have a mass similar to thick sour cream.

You can check the density with a conventional spatula. Scoop a little mixture on the tool and transfer it from the spatula to the spatula, it should not roll into lumps or spread.

- leave the finished mixture at the recommended time, usually 10-15 minutes, so that all components absorb moisture and gain the desired percentage of elasticity.

After all the procedures, gently mix the components and get ready to lay the tiles. The fastening material is applied using a comb with the necessary pitch of the teeth on a flat surface. After that, the lining is applied from above and pressed. Construction crosses are inserted in the joint area, which allow you to align the element with others and create a perfectly even seam.

VIDEO: 5 ways to tile. Which glue is better