Balconies and loggias are an integral part of many apartments and houses. Often, owners of residential real estate do not perform any repairs in these premises, saving money, however, this is considered the wrong decision. If decorating the balcony with your own hands, the step-by-step instruction of which is presented below will be executed correctly and efficiently, then a full-fledged living room will be obtained, which can be used for any purpose. Different materials can be used to decorate this building, but the use of special panels, which can be plastic, wood or some other, is considered the optimal solution. Clapboard decoration is an ideal choice, as the material has a beautiful view and is environmentally friendly. High-quality repair work carried out for loggias or balconies provides a beautiful and warm room.

Which materials to choose

For finishing work, a variety of materials can be used that provide an excellent result. The following options are considered the most popular.

| Material | Specifics of its application |

| Wooden lining | Lining the balconies and loggias is considered the best solution. This material is made of natural wood and also has a beautiful view. Photos of this design are very beautiful. Working with the material is simple, but it is considered expensive. |

| Siding | Its installation involves not only improving the appearance of the balcony, but also carries out additional work related to the insulation of this room. The siding is available in numerous colors, and is also equipped with special fasteners during the production process, guaranteeing a simplified installation procedure. |

| Moisture-resistant drywall | It is mounted on the crate, after which all received joints are closed. Such a coating may be coated with wallpaper, paint or other materials for decoration. This option does not require investing a large amount of funds in the repair work for the loggias. |

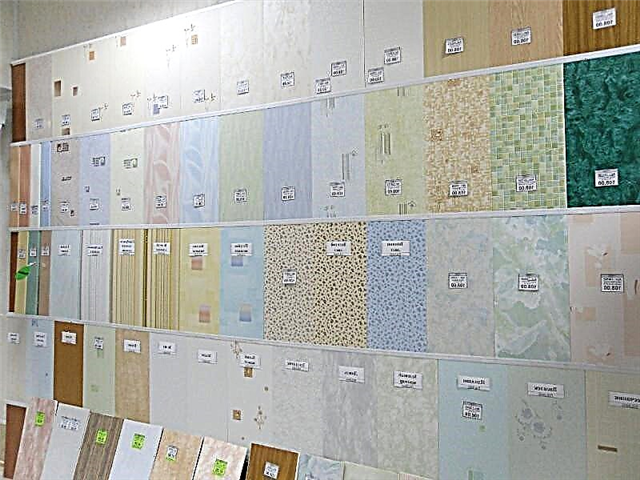

| Plastic panels | They are a good choice for a balcony, however, they do not have the required vapor permeability index, so a sealed finish is obtained. Available in numerous colors, so with their help you get an interesting and bright design. |

The above materials are considered the most relevant and often used in the process of finishing balconies. They make durable and beautiful coatings. Any person who does not have experience in this direction can carry out all the work on their creation.

Most often for loggias it is the lining which forms a beautiful covering. It is easy to operate, and is also treated under special production conditions with special protective compounds that prevent possible rotting or the development of microorganisms. Photos of such finishes are widely presented in the selection, so you can make sure the right choice of cladding for the surfaces of the balcony.

Lining

This material is a planed board with natural moisture. There is a subtype of building material called euro-lining. These are better products with profiles of complex geometric shapes, as well as ventilation ducts. In this case, the material is more demanding on the level of humidity in the room and the quality of the rough surface.

- Environmental friendliness. The material is 100% natural raw materials that do not pose a health hazard to people of any age category.

- Long term of operation. Provided that the lining is installed and used correctly, it can last up to 20 years.

- Easy installation. Products are equipped with a connecting system, so installation does not take much time. The novice master can finish the balcony in 1 day.

- Additional insulation. Despite the fact that the lining is a simple finishing material, it slightly protects the room from noise and retains heat.

Lining - one of the most popular finishing options for balconies and loggias

Lining - one of the most popular finishing options for balconies and loggiasDIY step-by-step instructions for finishing your balcony

If you plan to independently carry out repair work on the balcony, it is important to understand how to install all the details of the coating. A step-by-step instruction describes the sequential actions by which you can independently create the correct and high-quality design.

Initially, it is important to calculate the necessary materials for the upcoming work. For this, the size of the balcony itself, as well as the dimensions of the panels of the lining or other selected material, are taken into account. It is recommended that you initially purchase panels with a small margin, as a beginner can make mistakes that lead to the destruction of materials, which will significantly increase consumption.

Necessary materials and tools

Not only the panels themselves are purchased, but also additional materials that will be used in the process. If the walls of the balcony are uneven, it is advisable to form a crate, for which quality and properly dried wooden battens are used. Particular attention is paid to the acquisition of fasteners, which should not violate the integrity of the lining, but are required to ensure its optimal and reliable fastening.

It is important to prepare the following elements for work:

- since it is planned to clad the balcony with lining, quality material in the right amount is purchased,

- plastic film or other waterproofing material,

- wood slats, which must be of good quality and properly dried,

- insulation, which in size must correspond to the created cells in the frame, and the heat-insulating material can be represented by plates or rolls,

- self-tapping screws with which the fixing of the main structural elements will be performed, and it is desirable that they be galvanized, since in this case they are highly resistant to numerous negative factors,

- dowel nails,

- mounting foam, which ensures filling of joints formed during the operation,

- a drill and a screwdriver are prepared from the tools, as well as the level due to which a perfectly smooth design is obtained,

- since the walls of the balcony are covered with clapboard, it is important to prepare a jigsaw on a tree for cutting it, and it is also allowed to use a hacksaw.

In the process of cutting the lining, it is necessary to work only with goggles in order to avoid the possible contact of small and dangerous objects in the eyes.

Clapboard trim tool

Clapboard trim tool  Materials for thermal insulation

Materials for thermal insulation

Preparation of the surfaces of the balcony

Do-it-yourself balcony finishing begins with preparatory stages, which involve bringing all surfaces to the right look:

- the old coating is removed if it is on the walls of the balcony,

- surfaces are inspected for areas where mold or crumbling areas are present, since they must be eliminated,

- all surfaces are treated with special antiseptics,

- after drying the antiseptic, a primer is applied, for which you can use rollers, brushes or sprayers.

After preparation, the installation of the frame begins.

Preparing the balcony for decoration

Preparing the balcony for decoration

Crate Creation

Instructions for the formation of high-quality finish of the balcony with clapboard involves the formation of a reliable frame. It is to him that the selected materials for decoration will be fixed.

To create a frame, a wooden beam is usually used, and correctly dried and high-quality elements are selected. Their thickness completely depends on what parameters the panels selected for finishing have. It is taken into account whether insulation will be used in the process of finishing the loggias, since it can affect the parameters of the lathing.

Bars for wooden lathing

Bars for wooden lathing

Before using any wooden materials, which include wooden beams, it is important to cover them with high-quality antiseptics that increase their resistance to moisture.

Installing the frame is performed in the following sequential steps:

- marking is applied, with the help of which it will be clear in which places it is necessary to fix the main elements of the crate,

- profiles or slats are trimmed in such a way that they get exactly the same elements,

- nails or profiles are nailed or screwed to the walls, and the distance between them should be equal to the width of the panels used to decorate the loggias or balconies,

- the most commonly used beam, for the fixing of which dowels are used.

Photos of finished crates are presented below, so it’s very simple to understand their structure and design. At the same time, their parameters can be different, because they completely depend on the panels used, since the balcony is not always trimmed with lining. Often, other materials are used for this, which are also fixed to the frame.

As soon as the frame is ready, it is not recommended to immediately sheathe it with a lining, since it is desirable to fill its empty cells with insulation, which will provide a significant increase in the thermal insulation parameters of the room.

Horizontal crate

Horizontal crate  Crate on the balcony floor

Crate on the balcony floor

Construction insulation

Decorating loggias most often involves additional insulation. Since a crate is created that has empty cells, it is in these cells that the selected insulation is laid.

Thanks to the creation of a heat-insulating layer, the formation of a warm room is ensured. The optimal choice for loggias and balconies is foam, produced in slabs. Mineral wool is also often used, but its use is allowed only in conjunction with waterproofing films, since it is important not to allow water to get into the insulation, which negatively affects its basic parameters.

As a heater, foam can be used

As a heater, foam can be used

Also, the interior decoration often involves the use of foam during insulation. However, it is taken into account that it has poor vapor barrier parameters. Insulation plates must enter the cells very tightly.

Heat-insulating material is fixed with glue or polyurethane foam, but it is allowed to use different mechanical fasteners for these purposes. Photos of the finished result can be viewed below.

Insulation mount

Insulation mount

Waterproofing

The step-by-step instruction assumes that the next step in finishing the balcony with a lining is to cover the created frame with waterproofing materials. The most often chosen polyethylene film for these purposes is considered to be affordable and easy to use. However, there are a lot of types of modern membranes on the market, with the help of which excellent protection of the structure from moisture is provided. Their photos are presented in a selection, and usually one of their sides is foil.

If roofing material is chosen as a material for waterproofing, then before installation, the material must be heated from the mounting side. If it is planned to use polystyrene as a heater, then for its fastening plastic dowels or glue without toluene content will be required. This glue must be processed using a notched trowel mounting area. For more reliable fastening, dowels are located at the edges of the plates.

The reliability of the seal will allow for the additional use of sealant tape. Also, do not forget about such works as surface treatment of frames with special hydrophobic compounds, as well as the installation of ebbs that block the access of water under the frames.

Waterproofing the walls with plastic wrap

Waterproofing the walls with plastic wrap  Vapor barrier of the balcony with foil isolon

Vapor barrier of the balcony with foil isolon

Wall covering

The interior decoration further involves fixing the panels themselves. Most often you have to use a lining, which is distinguished by its beautiful view, ease of use and other positive parameters.

The whole process is divided into the following stages:

- work begins from a certain angle of the room, for which a starting element of plastic is fixed,

- installation is carried out using self-tapping screws, but it is allowed to use brackets and a stapler,

- the remaining sheets are connected to each other by the existing grooves and spikes,

- if there is a need to cut the panels, then a special hacksaw is used for this, designed to work with a specific material.

Thus, the decoration of the walls of the balcony with the help of lining is considered a simple and understandable process that everyone can handle.

Mounting the guide profile

Mounting the guide profile  Panel Mount

Panel Mount

For a full decoration of the loggias, it is important to pay attention to the floor. For this, the following structures are most often formed:

- the base can be made of cement, for which a screed is poured or self-leveling mixtures are used, and you can also make a structure on logs or a wooden floor,

- high-quality flooring is laid on top, and for balconies a terrace board, ceramic tile, laminate or linoleum are considered an excellent choice.

It is important to focus on those materials that will be resistant to changes in temperature or high humidity.

Ceiling

The interior decoration of the balconies affects the ceiling. The following finishes can be used for this:

- the formation of the same coating as on the walls, for which sheets of lining, plastic panels or other elements are used, moreover, they can be fixed directly to the base or a frame can be used,

- the use of whitewash for the ceiling,

- the creation of a suspended or suspended ceiling.

Each view has its own characteristics, so the choice depends on the purpose of the balcony and on the desires of its owners.

Stretch ceiling

Stretch ceiling  Drywall

Drywall  Plastic panels

Plastic panels

Lighting

Finishing is to create high-quality and bright lighting. Photos of the finished result are presented below in large quantities. For loggias, you can use not only standard chandeliers located in the center of the ceiling, but also spotlights, as well as LED strips.

Thus, the decoration of any balcony or loggia is a complex process, which consists in the implementation of a large number of actions. All of them are understandable and uncomplicated, so they can be done on their own.

Lining installation

Before sheathe the balcony inside, you should stock up on the following tools and consumables:

- Screwdriver, puncher or hammer drill, jigsaw.

- Square, construction level, tape measure.

- Hammer or ax, 3 cm nails, dowel nails up to 6x100, wood screws.

Tools and supplies needed to mount the lining on the balcony

Tools and supplies needed to mount the lining on the balcony Then you need to carry out the following preparatory work:

- Remove old coating and thoroughly clean base. Tap it with a hammer to identify weak fragments, they must be removed, and the resulting potholes should be coated with a cement-sand mortar or putty.

- Check the evenness of the walls. With a strong blockage, it is recommended to apply a rough plaster layer, on which the lining will subsequently be attached.

- Each product is thoroughly soaked with a special antiseptic composition.

Preparatory work before installing the lining

Preparatory work before installing the liningNext is the installation of the crate. This stage is laborious and responsible, therefore it is worth talking about it separately. The first thing you need to do is markup, the lines should be located 50-70 cm from each other and 10 cm from the walls. After this, you need to trim the wooden bars and drill holes for fasteners in them in increments of 15 cm. Using dowels and screws, the crate is installed on the wall.

Now you can start lining inside the balcony with your own hands:

- You need to take the first element, lean it against the crate and fix it on it, driving a nail in the middle of the spike.

- Then you need to take the second element and connect it to the first, introducing the spike into the groove.

- Thus finish the entire surface.

- Before installing the lining on the area near the walls and ceiling, the material will have to be cut with a jigsaw.

On a note! You can also use clamps instead of nails. Then the mount will turn out inconspicuous.

MDF panels

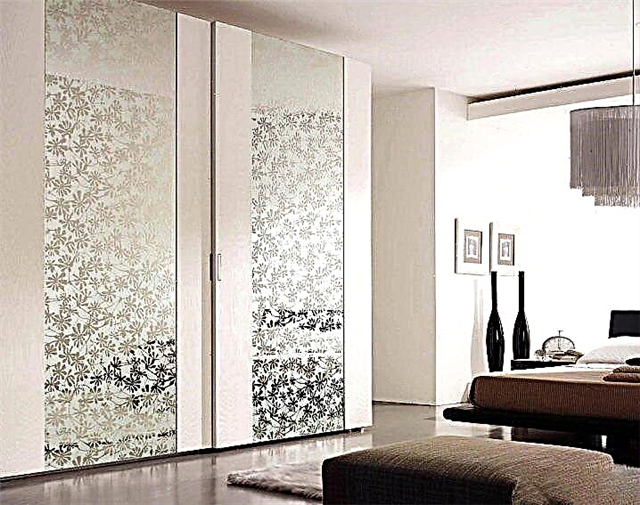

For covering the balcony, MDF panels are also used, which are wood fiber boards. The modern construction market offers several types of this material: flat products with a protective polymer coating on the front side and panels with embossed patterns.

- To trim the balcony with your own hands will require a minimum of funds, time and effort.

- Serious preparatory work is not required.

- Behind the panels you can hide wiring or other utilities, you can also lay insulation.

- The material is produced in a wide range of colors and in different sizes.

The design of the balcony MDF panels

The design of the balcony MDF panelsInstallation work

The lining of balconies from the inside begins with the preparation of the tool and the installation of the lathing. It should be noted that this material is somewhat similar to lining, therefore, it requires exactly the same preparatory steps. The only difference is that the panels can be installed on the crate of wooden battens or metal profiles. The installation process is as follows:

- The first element is installed in the corner. It is mounted on a clamp, but if such fasteners were not at hand, then an ordinary construction bracket will do.

- The next panel is installed in the groove of the previous one and is also fixed.

- After finishing the entire wall, plugs are installed on the edges of the coating.

The process of covering the balcony with MDF panels on a wooden frame

The process of covering the balcony with MDF panels on a wooden frame Plastic panels

To sheathe the balcony inside with their own hands, sometimes plastic panels are used. This building material is inexpensive and easy to install, so it has gained popularity among domestic users. It is a PVC sheet equipped with a connecting system.

The advantages of plastic material for decorating loggias and balconies:

- Wide range of colors. Thanks to this feature, you can create a unique interior on the balcony.

- Simple care. It is enough to wipe such a coating with a damp cloth or sponge.

- It can last up to 30 years. At the same time, it is resistant to temperature extremes, exposure to water and sunlight.

- Low cost. Plastic panels are currently considered the most affordable option for the inner lining of balconies.

As a budget finishing material for finishing a balcony, you can use plastic panels

As a budget finishing material for finishing a balcony, you can use plastic panelsMounting technology

The preparatory work is exactly the same as in the previous cases:

- Removing the old coating and preparing the rough surface.

- Measurements of the area, marking, installation of the crate.

- The acquisition of material with a margin of 10%.

- Acquisition of sound insulation.

The first profile is fixed with a self-tapping screw on the ceiling lathing. You need to start from above to make it easier to work. After that, you need to fix the profile in the center, which will be the guide. Under the installed elements, wiring is laid, as well as insulation. The entire ceiling is closed with panels using a spike-groove system. The last panel will most likely have to be cut. The walls are similarly finished. To make corners, use plastic plugs.

Drywall

Plastering the balcony with gypsum board is permissible only if coloring, applying decorative plaster, liquid wallpaper and so on will be made in the future. This material is quite popular for interior decoration, despite the fragility and soiling.

The positive aspects of drywall are as follows:

- Relatively low cost.

- Quick and easy installation.

Important! This material is made on the basis of gypsum, so it requires preliminary waterproofing.

Plating balconies and loggias with drywall

Before sheathe the balcony with drywall, it is necessary to prepare the surface and install the crate:

- Draw a line in the center of the ceiling and a few perpendicular to it.

- On the perimeter of the room at a distance of 5 cm from the ceiling, draw lines.

- Mark the ceiling through 1/3 of the length of the sheet of building material.

- Cut metal profiles to the desired size with scissors.

- Using dowels, fix the guides on the wall, and on the ceiling by means of an anchor connection.

- Starting from the corners of the balcony, install the profiles on the ceiling, and then on the walls on the dowels - in increments of 40 cm on the ceiling and 60 cm on the wall.

After that, you can start laying heat and sound insulating materials and, if necessary, utilities. Cut sheets of insulation are installed between the crate and the rough surface. The resulting structure is covered with foil, securing it with a stapler. Now you can sheathe the balcony from the inside with drywall.

The procedure for the work is the same as in the case of the crate: first, work is carried out on the ceiling, then on the walls.

- The first step is to prepare the material. To do this, the sheets are cut to the required dimensions and chamfered (slightly grind the edge so that it is later easier to putty the seam).

- The first element is mounted 20 cm from the corner on the screws with a step of 15 cm. The hat needs to be drowned in the surface, but it is important not to overdo it so that the sheet does not crack.

- Similarly, the remaining sheets are installed on the main area of the ceiling and walls. At the end, small fragments of material are mounted in the corners and begin to putty.

- A primer is applied to the finished coating, and after it dries, a thin layer of putty is applied.

- While the material has not yet dried, they lay a sickle on it and cover it with a thicker layer of putty.

- At the end of the surface they are primed again in order to prepare for further finishing.

Plasterboard-trimmed balcony, ready for further decoration

Plasterboard-trimmed balcony, ready for further decorationSiding

Typically, this material is used for finishing facades, but it is permissible to use it inside the balcony. Products are made on the basis of vinyl, therefore they have the following advantages:

- A good indicator of resistance to weathering (precipitation, wind).

- The absence of substances harmful to human health in the composition.

- A good level of ventilation, ensuring timely removal of moisture from under the coating.

- The material well tolerates the effects of high and low temperatures, so installation work can be carried out at any time of the year.

- Possibility of spot repair.

Siding is rarely used for interior decoration of a balcony, most often it is used for facade work

Siding is rarely used for interior decoration of a balcony, most often it is used for facade workInstallation of siding inside the balcony

Preparatory work, tools and supplies are exactly the same as in previous cases. Inside, the balcony may be damp, so it is better to treat all surfaces with an antiseptic and lay waterproofing material.

Installation of siding begins with the installation of the frame for the panels. Wooden slats are stuffed on the ceiling at a distance of 40 cm, on the wall - 50 cm. The cross rails are mounted at a distance that is 5 cm less than the length of the element. The lath is mounted on dowels.

Before installing the siding, it is necessary to erect a wooden frame and lay waterproofing material

Before installing the siding, it is necessary to erect a wooden frame and lay waterproofing material

You should know! Before starting the installation, it is recommended to treat the crate with an antiseptic.

Then lay the insulation. A thermal insulator is mounted in the formed voids of the frame and fixed with a waterproof film. As a result, the balcony will turn into a warmed room.

Now we will consider how to properly sheathe a balcony with siding. First of all, special guide profiles are mounted on the crate, after which the siding is cut to the required size using metal scissors. Indents do not need to be done, the first panel is placed right in the corner and fixed with a self-tapping screw. For its wide part, the tab of the next panel is wound and also secured. Thus, the entire area is finished. At the end, plugs are installed at the corners and edges of the coating.

Installation of special guide profiles for siding

Installation of special guide profiles for siding

Sandwich panels

This material has a three-layer structure. The outer layers are made of metal, and the inner one is a heater, for example, mineral wool. Sandwich panels are a popular option for decorating a balcony, due to the following features:

- Safety and environmental friendliness.

- High rates of heat and noise insulation.

- Light weight, which reduces the load on the balcony and makes installation easier.

- No need for further decoration.

- Pathogens cannot develop on the surface.

Sandwich panels are often used to decorate a balcony, due to their sound and heat insulating properties.

Sandwich panels are often used to decorate a balcony, due to their sound and heat insulating properties.Panel Installation

- The installation process begins with fixing the fasteners: the inner corners and the final parts on the crate.

- Preparatory work is the same as in the case of the above materials.

- If the panels are planned to be mounted to the ceiling, then the first thing to do is install the baseboard at the top of the battens.

- The first panel is installed on a metal or wooden frame in a corner closer to the ceiling. It is fixed with a self-tapping screw, after which the next element is inserted into the groove. The rigidity of the structure is ensured by a reliable thorn-groove connection, so you can do without additional fastening of each part with self-tapping screws.

- Before installing the next item, you need to check the evenness of the current installation. It is also important to ensure that gaps and backlashes do not form.

- After finishing the entire wall, it is necessary to install additional elements on the edges and external corners of the material.

- The design is checked by the building level, after which it can be operated.

Sandwich paneling for a balcony requires the construction of a frame

Sandwich paneling for a balcony requires the construction of a frame Conclusion

The better to sheathe the balcony inside, each owner will decide for himself. The above materials are not very different in cost, the exception is sandwich panels, since they already have insulation. The balcony area is small, which also positively affects the cost of work. It does not matter what exactly will be chosen as the material for decoration, the main thing is to follow the above recommendations and do not forget to check the correct installation of the products by level.