Article published: Nikolay Strelkovsky

The modern system of warm water floors is identified with a high level of coziness and comfort. Such a floor effectively heats the room and does not have a harmful effect on the life and health of residents. Such results can only be achieved if the calculations are correctly performed and the installation work is properly carried out.

Calculation of underfloor heating

A warm water floor can be the main source of heating for a dwelling or serve as an auxiliary heating element. The main calculations of such floors are based on the data of the work scheme: easy heating of the surface to improve comfort or providing full heat to the entire area of the room. The implementation of the second option involves a more complex design of the heated floor and a reliable adjustment system.

Schedule of comfortable temperature conditions

Calculation Data

Calculations and design are based on several characteristics of the room, as well as the choice of heating option - primary or secondary. Important indicators are the type, configuration and area of the room in which the installation of this type of heating system is planned. The best option is to use a floor plan indicating all the parameters and dimensions necessary for the calculations. It is allowed to independently perform the most accurate measurements.

The schedule for calculating the warm floor

To determine the magnitude of heat loss, the following data will be required:

- type of materials used in the construction process,

- glazing option, including type of profile and double-glazed window,

- temperature indicators in the region of residence,

- use of additional heat sources,

- exact dimensions of the area of the room,

- the estimated temperature in the room,

- floor height.

In addition, the thickness and insulation of the floor, as well as the type of floor covering intended for use, are taken into account, which directly affects the efficiency of the entire heating system.

When performing the calculations, the temperature desired for the premises to be equipped should be taken into account.

The consumption of the floor heating pipe, depending on the step of the loop

| Pitch mm | Pipe consumption per 1 m2, m p. |

|---|---|

| 100 | 10 |

| 150 | 6,7 |

| 200 | 5 |

| 250 | 4 |

| 300 | 3,4 |

Design Features

All calculations of underfloor heating should be done very carefully. Any flaws in the design can be corrected only as a result of complete or partial dismantling of the screed, which can not only damage the interior decoration in the room, but also lead to significant costs of time, effort and money.

Recommended temperature indicators of the floor surface depending on the type of room are:

- living room - 29 ° C,

- sections near the outer walls - 35 ° C,

- bathrooms and areas with high humidity - 33 ° C,

- under parquet flooring - 27 ° C.

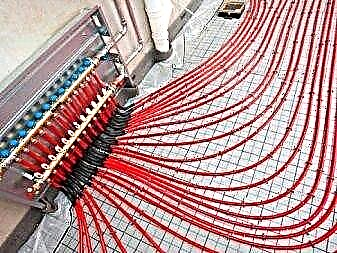

Short pipes require a weaker circulation pump, which makes the system economically viable. A circuit with a diameter of 1.6 cm should not be longer than 100 meters, and for pipes with a diameter of 2 cm, the maximum length is 120 meters.

Decision table for choosing a water floor heating system

Calculation Rules

To perform a heating system on an area of 10 square, the best option would be:

- the use of 16 mm pipes with a length of 65 meters,

- the flow rate of the pump used in the system cannot be less than two liters per minute,

- the contours should have an equivalent length with a difference of not more than 20%,

- the optimal distance between the pipes is 15 centimeters.

Please note that the difference between the surface and coolant temperature can be about 15 ° C.

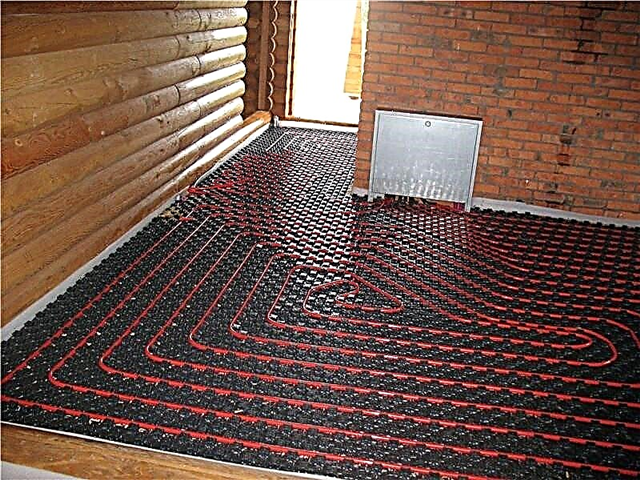

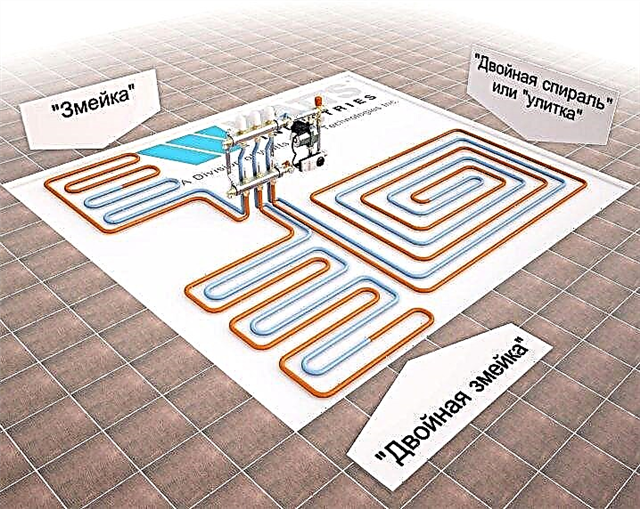

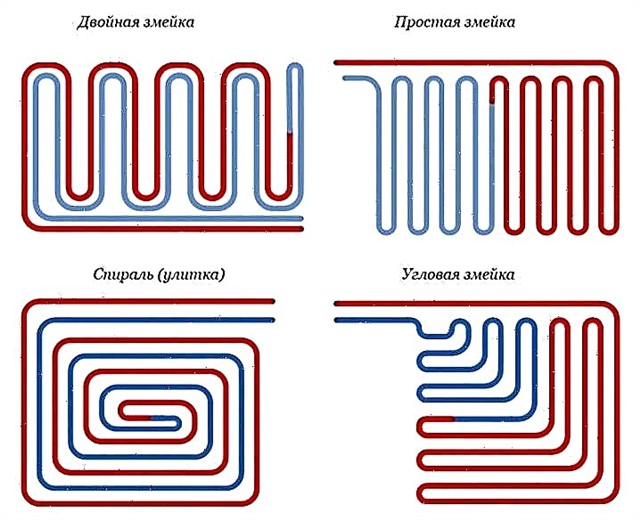

The optimal method for laying the pipe system is represented by a "snail". It is this type of installation that contributes to the most uniform distribution of heat over the entire surface and allows to minimize hydraulic losses due to smooth turns. When laying pipes in the area of external walls, the optimal pitch is ten centimeters. To perform high-quality and competent fastening, it is advisable to carry out preliminary marking.

Heat consumption table of various parts of the building

Pipe and power calculations

The data obtained as a result of measurements are the basis for calculating the power of equipment such as a heating heat pump, gas or electric boiler, and also allow you to determine the distance between the pipes during installation work.

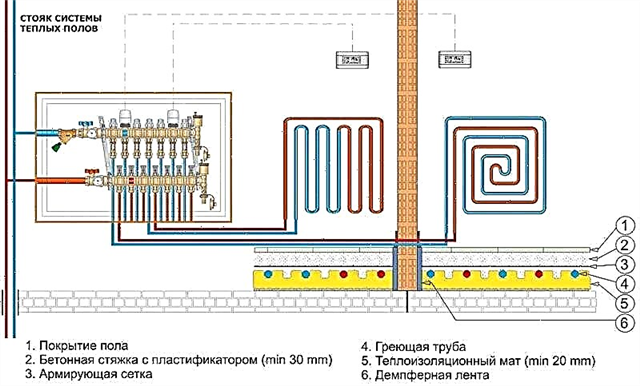

Fastening pipes to reinforcing mesh

In order to correctly calculate the length of pipes necessary for laying, it is necessary to determine the type and features of these elements:

- stainless corrugated type of pipes is characterized by efficiency and high-quality heat transfer,

- copper pipes are characterized by a high level of heat transfer and an impressive cost,

- cross-linked polyethylene pipes,

- metal-plastic version of pipes with an ideal ratio of quality and cost,

- foam pipes with low thermal conductivity and affordable price.

Corrugated pipe for underfloor heating - one of the best options for water floor heating

Significantly simplify the calculations and make them as accurate as possible allows the use of special computer programs. All calculations must be carried out taking into account the installation method and the distance between the pipes.

The main indicators characterizing the system are:

- the required length of the heating circuit,

- uniform distribution of heat released,

- the value of the permissible limits of the active heat load.

It should be borne in mind that with a significant area of the heated room, it is allowed to increase the installation step with a simultaneous increase in the temperature regime of the coolant. The possible range of pitch when laying is from five to sixty centimeters.

The most common ratios of distances and thermal loads:

- a distance of 15 centimeters corresponds to a coolant from 800 W per 10 m²,

- a distance of 20 centimeters corresponds to a coolant from 500 to 800 W per 10 m²,

- a distance of 30 centimeters corresponds to a coolant of up to 500 W per 10 m².

In order to know for sure whether it is enough to use the system as the only source of heating, or whether “underfloor heating” can only serve as an addition to the main heating, it is necessary to perform a rough, preliminary calculation.

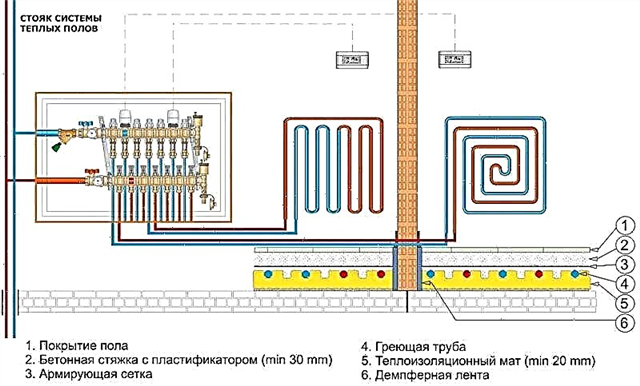

Scheme of connecting a water heated floor to the boiler

Draft heat circuit calculations

To determine the density of the effective heat flux given off m² of underfloor heating, you must use the formula:

g (W / m²) = Q (W) / F (m²)

- g is a measure of the density of the heat flux,

- Q - the total heat loss in the room,

- F - the proposed floor area.

To calculate the Q value, the area of all windows, the average height of the ceilings in the room, and the thermal insulation characteristics of floors, walls, and roofs are taken into account. When performing underfloor heating as an additional, it is advisable to determine the total amount of heat loss in the form of a percentage ratio.

When calculating the value of F, only the floor area involved in the process of heating the room is subject to accounting. In areas where interior items and furniture should be left, free zones should be left with a width of about 50 centimeters.

To determine the average temperature of the coolant in the conditions of the heating circuit, the formula is used:

ΔТ (° С) = (TR + TO) / 2

- TR - temperature indicator at the entrance to the heating circuit,

- THAT - temperature indicator at the exit section of the heating circuit.

Recommended temperature parameters in ° C for inlet and outlet for a standard coolant are: 55–45, 50–40, 45–35, 40–30. It should be noted that the temperature indicator for the feed can not be higher than 55 ° C, with the condition of the temperature for the return circuit with a difference of 5 ° C.

In accordance with the obtained values of g and ΔТ, the diameter and pitch are selected for the installation of pipes. It is convenient to use a special table.

Tables for calculating heat flux for a warm floor depending on the flooring material

Tables for calculating heat flux for a warm floor depending on the flooring material

Tables for calculating heat flux for a warm floor depending on the flooring material

Tables for calculating heat flux for a warm floor depending on the flooring material

At the next stage, the approximate length of the pipes involved in the system is calculated. For this purpose, it is necessary to divide the indicator of the area of the heated floor in m² by the distance between the laid pipes in meters. To the obtained indicator, add the margin of length for bending and connecting to the length, add the length to the bends of pipes and the length to connect to the collector system.

With the known length and diameter of the pipes, the volume indicator and the coolant velocity are easily calculated, the optimal value of which is 0.15-1 meter per second. At higher speeds, the diameter of the pipes used should be increased.

The correct choice of the pump used in the heating circuit is based on the amount of coolant flow with a margin of twenty percent. Such an increase in the indicator corresponds to the parameters of hydraulic resistance in the pipe system. The selection of sediment for the circulation of several heating systems is in accordance with the power indicators of this equipment with the total consumption of all used heating circuits.

Calculation of the cost of underfloor heating

Tips & Tricks

In order to obtain the most accurate calculations, it is advisable to seek the advice of professionals specializing in the installation of internal engineering communications.

You can use the online calculator, which will facilitate the calculations, but it will give very rough calculations that provide general information about the scope of the upcoming installation work.

An example of calculating a water floor heating

To heat old and dilapidated buildings that do not have high-quality insulation, it is inappropriate to use a system of warm water floors as the only heating element, which is due to a low degree of efficiency and a high level of energy consumption.

The level of technical literacy of all performed calculations has a direct impact on the quality characteristics of the installed heating system. Correct calculations can optimize financial costs not only for the installation of water floor heating, but also minimize costs during operation and maintenance of the entire heating system.

Stages of calculating the thermal floor

After determining the shape of the contour, the dimensions of the pipeline are calculated in accordance with building codes. The calculation of the pipe for the warm floor depends on the material of the product. About what calculations need to be done before laying water heating, see this video:

Materials such as stainless steel, copper, polyethylene, expanded polystyrene and metal-plastic products are used. Each material has its own coefficient of thermal conductivity. Depending on the heat transfer of the material, you can choose the optimal pitch and calculate the length.

The volume of fluid filling the heating system is an important indicator

The volume of fluid filling the heating system is an important indicator

The calculation of warm water floors continues with the calculation of the volume of liquid that the system needs to be filled. This indicator directly depends on the diameter and length of the pipeline. The fluid circulation rate in the system is determined taking into account the parameters of the pipeline, such as the inner diameter of the tube and the pressure for which it is designed.

Based on the collected data, the power of the warm water floor is determined. This indicator allows you to choose equipment to maintain temperature and pressure in the system.

In private homes, you can use a heat pump. When using it, a chimney is not required, the system will work without connecting to the ventilation shaft.

In private homes, you can use a heat pump. When using it, a chimney is not required, the system will work without connecting to the ventilation shaft.

Alternatively, you can connect the floor heater to the heating system. In apartments, the best option would be to use a small electric heater. Read more about the device of heated floors in this useful video:

Of course, underfloor heating will increase the overall level of comfort. Also, the result of this work will affect the attractiveness of real estate in case of sale. The energy efficiency of such systems allows you to save on heating, maintaining a comfortable temperature level in the autumn, winter and spring.

Subtleties of calculation

In most cases, 5 m of pipe is consumed per 1 m2. Moreover, the step length is 20 cm.

However, experts recommend laying pipes on the basis of accurate calculations. For this purpose, the formula L = S / N * 1,1 is required, where:

- S represents the area of the plot,

- N denotes a stacking step,

- 1,1 - spare pipe needed to create turns.

If you add the distance from the collector to the floor, doubled, you get a more accurate calculation. For a better understanding of the calculations, you can give an example:

- suppose the area of the plot is 16 m2,

- the distance from the collector to the floor is 3.5 m,

- laying pitch is 0.15 m,

- following the formula: 16 / 0.15 x 1.1 + (3.5 x 2) = 124 m.

The increase in flow depending on the distance between adjacent pipes is presented in the following table:

Pipe consumption per 1 m2, m.

The layout of the warm floor limits the length of the pipe to 120 m, because there are a number of reasons for this:

high temperatures should not damage the floor,

heating in the circuit during operation (especially during leakage) can damage the cement screed,

dividing the surface into several sections contributes to efficient heating.

In diameter

For the correct calculation of the pipe diameter, the following calculations will be required:

15kPa - pressure of the pump providing efficient heating,

the length of the pipes is 85 m,

coolant consumes 0.2 m³ / h.

Therefore, the calculation is performed according to the formula D = 18 * (p / L * G2) - 0.19, where:

D denotes the diameter of the pipe for the warm floor,

L - meter length of the product,

p is the pressure of the pump,

G is the flow rate of water that circulates in the pipes (described in the documentation),

D = 18 * (15/85 × 0.22) –0.19 = 13.6 mm.

Manufacturers produce 16 mm pipes - the most optimal option for installing the system. Suitable schemes for setting the thermal floor are considered a snake and a snail. When planning water, hot water is red, cold is indicated in blue.

Along the length of the contour

The heating system needs to create a structure that supports the most effective pressure and air circulation. Therefore, the limit of the length of the water circuit is 80, maximum 100 meters. However, the room does not always correspond to the calculations, requiring its own parameters, sometimes exceeding 150 m. The problem is solved easily - it is enough to establish several circuits.

For example, if a room requires 240 m of pipe, then three structures of 80 m should be created. In this case, the contours do not necessarily correspond to each other. According to experts, the difference can be up to 15 meters.

In the calculations, it is necessary to take into account the diameter of the pipe and the material of manufacture:

Plastic products are most in demand due to low cost and easy installation. The basis was laid polyethylene with a layer of aluminum, which increases the reliability of the structure. The metal has a high thermal conductivity, which attracts manufacturers who want to create optimal heat transfer conditions. With a diameter of 16 mm, the length of the contour can reach hundreds of meters.

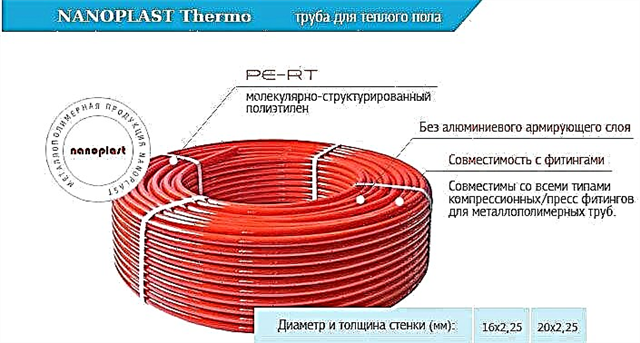

Polyethylene constructions do not require an additional layer, crosslinking at the molecular level. The product easily bends, showing resistance to high temperatures up to 95ºC and to various chemical solvents. At 18 mm in diameter, the limit is 120 meters.

Polypropylene has high rigidity and strength. It is not in demand on the market and is mainly used for production purposes. The length limit for the product is 90-100 meters.

Copper products have the highest thermal conductivity, due to which their price is the highest in the construction market. However, they need a professional installation, as they give leaks at the slightest fault.

Corrugated tubes are made of stainless steel. The maximum contour length is 120 m with a diameter of 25 mm. Corrugated pipes are recommended to be purchased with a pre-calculated length sufficient for one circuit. Such a purchase automatically eliminates the possibility of leaks.

A large area should be divided into component sections in a ratio of 1: 2. That is, its width will be 2 times less than the length. Therefore, in order to calculate the number of plots, the following measures will be required:

At a step of 15 cm, the number of m2 for the plot area does not exceed 12,

20 cm pitch suitable for 16 m2

25 cm pitch - 20 m2

Subsequently, with a step increment of 5 cm, the area accordingly increases by 4 m2. However, experts do not recommend calculating the exact values. To avoid leaks, take 2 m2 in reserve.

What factors should be considered?

In order to make all the necessary calculations that will help determine the amount of materials for a warm floor, the following should be considered:

total area of the room where floor heating will be equipped. It is from this figure that the number of circuits in the system will depend,

How to calculate the area of a room

It is important to remember that each heating circuit can only be connected to one collector,

layout of rooms where heating is arranged,

Options for laying heating cable

- sizes of windows and other places where heat will be lost. Type of glazing. Types of doors,

- the thickness of the walls of the house can also affect the power indicator,

- indoor air humidity

- the location of furniture and other interior items in the room. Underfloor heating does not fit under it if it is electric, since ventilation will be insufficient and the system may be damaged. Yes, and excessive heat can also adversely affect the safety of furniture and appliances,

- purpose of the room where the installation will be carried out. Depending on this, the heating power is selected,

- other heat sources and their power.

When calculating a warm floor, you need to consider many points

The temperature regime in the region and the need for heating a particular room, adjusting the temperature in it may turn out to be important. The power of the floor can be significantly affected by the type of finish flooring - some materials easily pass thermal energy, others worse.

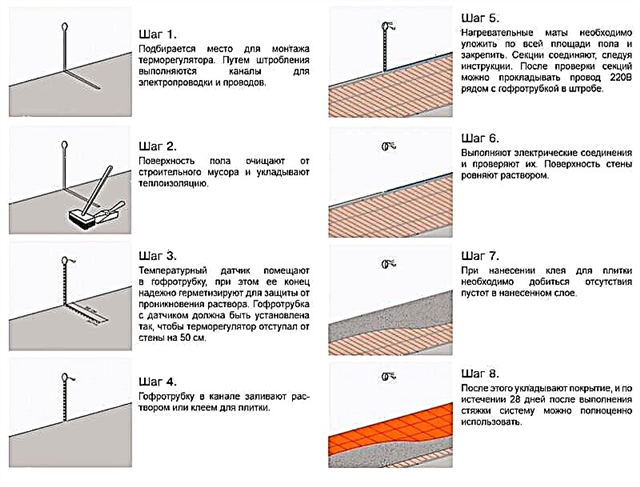

Installation scheme for electric universal heating mats for underfloor heating

Parameters for calculating the heat circuit

At the design stage, it is necessary to solve a number of issues that determine the structural features of the underfloor heating and operation mode - to choose the thickness of the screed, pump and other necessary equipment.

The technical aspects of the organization of the heating branch largely depend on its purpose. In addition to the purpose, for an accurate calculation of the footage of the water circuit, a number of indicators will be needed: coverage area, heat flux density, heat carrier temperature, type of flooring.

What is a water floor heating?

A warm water floor is a system of pipes hidden under a screed, through which water of a certain temperature circulates at about + 45 ° C. Today, this is the most popular technology for heating private homes. Thanks to the circulation of water inside the system, the heating is uniform and comfortable, unlike radiator heat distributors. Simplicity of design, independence from seasonal heating, temperature and pressure surges are another big plus of this technology. Such a system is heated mainly using a gas boiler. But without any problems interacts with other types of boilers.

Heated floors are mounted from polyethylene or plastic pipes. These materials are quite flexible and conduct heat well. For temperature control in such a system, the pump, collector and thermostatic mixer are responsible.

Advantages of a water floor heating:

- compatibility with many types of flooring - you can choose any covering you need without worrying that the heating system will damage it,

- heat saving - the system heats from below, due to this all cold air rises up, which allows heating the room without using other heat sources,

- seasonal options - in the cold season, the system acts as a heating structure, and in the summer is able to cool the room.

However, there are features that you need to familiarize yourself with before installing such a system:

- More expensive radiator system. When installing a house with a warm floor, get ready for increased expenses that will not particularly pay for themselves, but at the same time will bring a lot of pleasant things in terms of heating.

- Doesn’t cope with warming up everywhere. In most cases, the underfloor heating passes as the main heating, but there are rooms where an additional heating device is required. To clarify this fact, you need to do the calculation of the warm floor.

- Prohibition of use in apartment buildings. But it concerns mainly Russia. In other countries there are no restrictions.

This technology is more appropriate in a private house than an apartment. It is advisable to entrust the installation of the system to the masters, since there is a likelihood of leakage, which does not occur immediately. Poor assembly can cause a lot of trouble and cause serious damage to property.

Calculation of heat loss at home

Before calculating a water floor heating, you must first calculate the heat loss at home. Heat loss is the amount of heat that a room loses per unit of time. To reduce heat loss, heating devices are used, for example radiator heaters, heating pipes, and also a warm floor. In addition, it is possible to reduce heat loss when installing double-glazed windows and insulating walls with various materials that can retain heat indoors.

Calculation of heat loss is an important parameter in the design of residential premises. It is necessary to consider:

- room area

- the area of all windows

- ceiling height

- number of exterior walls

- outdoor temperature

- type of windows

- wall insulation

- type of room above.

Basically, heat loss depends on the difference in temperatures outdoors and inside, as well as the degree of thermal insulation of windows, walls, partitions. For a more accurate calculation of heat loss, you can use one of the many online calculators. They are quite simple and understandable to use, just enter the necessary values and the calculation will be performed automatically. In such calculators it is possible to calculate heat loss through windows, ceilings, walls, floors. This will provide detailed information on the basis of which the capacity of the heating equipment should be calculated.

It is believed that a warm floor will cope if heat loss does not exceed 100 watts per square meter. If this indicator is exceeded, you will have to resort to installing an additional heating device.

Detailed calculation of water floor heating

When making the calculations, please note that the maximum optimal temperature of the floor surface will be a value of 28 degrees. If this value is exceeded, discomfort may appear. In those places where the floor borders with windows or doors and external walls, the temperature can be higher up to + 35 ° C, and in bathrooms up to + 33 ° C.

Pay attention also to the coating that you intend to use, since each coating has its own heat transfer resistance. The recommended value should not exceed 0.15 M2K / W

When calculating a water floor heating, pay attention that the maximum temperature of the coolant must not exceed a value of 55 degrees. The optimum loop loss is usually 10 degrees. That is, if your feed is 50 degrees, then the return will be in the region of 40 degrees

The heat flux density per 1 m 2 is calculated as follows:

Using the obtained value of the heat flux density (q), room temperature and temperature on the floor surface, we calculate the necessary temperature difference between the heat carrier and the step of unfolding the pipe using the corresponding table (attached in the example). Further, using the formulas G = 3.6 * Q / 4.187 * (tz-tp ) and L = F / b, we calculate the required water flow through the floor heating system and the length of the pipe to be laid, where:

An example of calculating a warm floor

By calculating the heat loss, we found that in a particular room they are 1200 watts. We also know that we want a room temperature of 20 degrees. The usable floor area is 20 squares. There will be parquet on the floor. The thermal resistance of the parquet is 0.1 m2K / W.

To begin, let's determine the density of the heat flux per one square of the area.

According to the calculation table, we can get the desired temperature of 20 degrees with a pitch of 25 cm. In this case, the surface temperature of the floor will be 25.3 degrees.

You can find more tables, as an option, in the book "Metal-polymer pipes and fittings" from the company Egoplast.

It is not difficult to determine the length of the pipe

We find the water flow rate by the formula G = 3.6 * Q / 4.187 * (tz-tp ) The temperature according to the table is 50/40.

These data will help when setting values on the flow meters of the distribution manifold.

For our conditions, we need to lay out 80 meters of pipe in 25 cm increments. This is the ideal length of the circuit. If the value exceeds 90-100 meters, it is advisable to divide the room into two circuits.

Is it possible without calculations?

Calculations are optional. But we recommend that you nevertheless make calculations of heat loss at home to make sure that the warm floor will pass or not. If the floors pass, we follow a simple method. We lay the warm floor with a step of 15 cm, and in the zones of the outer walls with a step of 10 cm.

Next, we install room thermostats, connect to the servos on the collector and enjoy an excellent adjustable heating system.

What can affect heat transfer?

To begin with, I would like to dwell on what should be the correct and high-quality warm floor, regardless of which heat carrier - electricity or water - it will work. So, the heating system will work differently depending on the thickness of the base or the quality of the heat insulator, which means that all these points must be taken into account. It is believed that the thickness of the insulating material should not be more than 3 cm, while it is better to purchase the material with a reflective layer - so it will be easier to keep heat indoors.

Advice! As a heat insulator, it is advised to purchase polystyrene foam with a density of about 35 kg / m 3.

DIY floor heating

The thickness of the concrete screed should be about 4-10 cm, especially when it comes to laying a cable or water floor. Inside, it has reinforcement with a reinforcing mesh, on which, by the way, coolants can be fixed. Due to this, heat will be redistributed better. If it is planned to equip the water floor, it is recommended to purchase pipes made of metal-plastic or cross-linked polyethylene with a diameter of 16-20 mm - with them it is easiest to endow the system with optimal power sufficient to warm the rooms.

Screed floor heating scheme

Pipe for underfloor heating

Pipe coverage

When determining the dimensions of the base for laying pipes, a space is taken into account that is not cluttered with large equipment and built-in furniture. You need to think about the layout of items in the room in advance.

If the water floor is used as the main heat supplier, then its capacity should be sufficient to compensate for 100% of heat losses. If the coil is an addition to the radiator system, then it must cover 30-60% of the heat energy costs of the room

Heat flow and coolant temperature

The heat flux density is a calculated indicator characterizing the optimal amount of heat energy for heating a room. The value depends on a number of factors: the thermal conductivity of the walls, floors, glazing area, the presence of insulation and the intensity of air exchange. Based on the heat flux, the loop laying step is determined.

The maximum indicator of the temperature of the coolant is 60 ° C. However, the thickness of the screed and the floor covering bring down the temperature - in fact, about 30-35 ° C is observed on the floor surface. The difference between the thermal indicators at the input and output of the circuit should not exceed 5 ° C.

Type of flooring

Finishing affects system performance. Optimum thermal conductivity of tiles and porcelain stoneware - the surface heats up quickly. A good indicator of the efficiency of the water circuit when using a laminate and linoleum without a heat-insulating layer. The lowest thermal conductivity of a wooden coating.

The degree of heat transfer also depends on the fill material. The system is most effective when using heavy concrete with natural aggregate, for example, marine pebbles of fine fraction.

Cement-sand mortar provides an average level of heat transfer when heating the coolant to 45 ° C. The efficiency of the circuit drops significantly when the device is semi-dry screed

When calculating pipes for a warm floor, the established norms of the temperature regime of the coating should be taken into account:

- 29 ° С - living room,

- 33 ° C - rooms of high humidity,

- 35 ° С - passage zones and cold zones - sections along the end walls.

The climatic features of the region will play an important role in determining the density of the laying of the water circuit. When calculating heat losses, the minimum temperature in winter must be taken into account

As practice shows, preliminary warming of the entire house will help reduce the load. It makes sense to first insulate the room, and then proceed to the calculation of heat loss and the parameters of the pipe circuit.

Fundamental rules

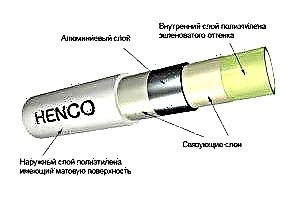

HENCO plastic pipes will serve well for your floor

The pipes used in the installation of water heating systems have special requirements. First of all, they should be characterized by durability, and their material should not be subjected to corrosion and destruction under extremes of temperature and pressure. In addition, they must be resistant to chemicals and microorganisms. Their service life should be at least 50 years.

Each circuit of the water floor heating system should consist of a single segment, since leaks can occur at the joints. For this reason, all consumables must be airtight. Leaks can also form in places of bends, which is characteristic of materials with low elasticity. Pipes from the following materials correspond to all these requirements:

- metal plastic

- crosslinked polyethylene,

- copper

- polypropylene

- steel.

Pipe for underfloor heating

In accordance with the standards for underfloor heating, cast iron is prohibited when installing them. Copper and steel are considered the best, but they are unpopular due to their high cost. Polypropylene is as unpopular as copper. However, its unpopularity is due not to a high cost, but to a large bend radius, which allows laying pipes with a minimum pitch of 32 cm, which in most cases is not enough.

Underfloor heating equipment

Therefore, the most popular today are metal-plastic and cross-linked polyethylene. Moreover, the latter has higher characteristics. The only drawback of cross-linked polyethylene is its poor elasticity: such pipes must be rigidly fixed to the reinforcing mesh during installation. If this requirement is not observed during operation, they can be bent.

How to calculate the pipe for a water floor heating?

Water floor heating is a system of interconnected pipes, which are then connected to the collector. Corrugated, copper (very expensive) or metal-plastic products are taken as consumables. The type of pipes should be taken into account by your calculator of the heated floor, because the material of their production not only affects the cost of installing the system, but also on the thermal characteristics. But to calculate the flow rate of pipes for a warm water floor per square meter, just the type of consumables is not enough.

The area on which the system will be laid.

It is called useful. It is calculated very simply. It is necessary to subtract from the total area of the room the area that will be occupied by stationary pieces of furniture - a kitchen, a sofa or a bed with boxes, cabinets, etc. To make it easier to calculate the pipe for a warm floor without a calculator, experts suggest making a graphic drawing. The plan of the room where the installation will be performed, or the entire apartment with the marking of usable areas. Now, it will not be difficult to calculate the water floor heating by area - you need to add up all the usable areas.

Type of pipe laying.

There are several options - “snake”, “snail”, “double snake” and “corner snail”. Pipe mounting forms can be combined.

Usually, a “snake” is chosen when organizing an auxiliary heating system for rooms of small size. It also makes sense to ask how to calculate the length of the pipe for a warm floor, taking into account the installation of the "snake" and the owners of private houses with high-quality external insulation. In rooms with little heat loss, this method of installing pipes will be effective. The fact is that it involves placing the product in a sinusoid with a pull along the walls. Therefore, in large rooms (pipe length over 65 m), the surface temperature can fluctuate greatly - over 90 ° C. This flaw is slightly eliminated by the “double snake”. Therefore, you need to use that online calculator of warm water floor, which takes into account the useful area and type of installation of pipes.

In voluminous spaces of standard geometry (without designer excesses) - a rectangle, square, circle - it is more convenient to use the “snail” laying type. The method is also called the "spiral". It involves fixing the pipe along the walls, followed by a bend of 900 and twisting. The method allows you to effectively alternate the pipe "feed" and "return". Its application not only simplifies the calculation of the pipe for a warm floor per 1 m2, but also allows you to organize uniform heating of the surface.

Step - the distance between adjacent products. It should not exceed a mark of 30 cm. This limitation is associated with the inefficiency of the warm floor. When walking on it, the feet of a person should not feel the temperature difference. When installing pipes in increments of more than 33 cm, this effect will be very noticeable. Any online calculator for underfloor heating pipes takes this parameter into account.

There is a restriction for the boundary zones. Here the pipes are placed in increments of 10 cm. In the rest of the zone, the parameter is increased by 5 cm (usually). That is 15, 20 and 25 cm. The larger the pitch, the less heat in the room and the less volume of consumables will be required. Therefore, if you do not know how to calculate the length of the pipe for a warm water floor, remember the purpose of the heated area and personal comfort requirements. If this is a bedroom with poor central heating, then 10-15 cm. If the corridor, 20-25 cm. But an increase of 5 cm is not categorical. The step can be both 17.5 cm and 11.5 cm. It is more convenient to calculate it according to the area and purpose of the room, given the heat transfer of the warm floor, which you can see from the table above.

How to determine the optimal room temperature

In this case, no particular difficulties arise. For orientation, you can use the recommended values, or come up with your own. Moreover, the floor covering is necessarily taken into account.

The floor of the living room should heat up to 29 degrees. When the distance from the external walls is more than half a meter, the floor temperature should reach 35 degrees. If the room is constantly high humidity, you will need to heat the floor surface to 33 degrees.

If the house has wooden parquet laid, the floor must not be heated above 27 degrees, as the parquet may deteriorate.

The carpet is able to retain heat, it makes it possible to increase the temperature by about 4-5 degrees.

Pumping equipment for underfloor heating calculations

Lowering the temperature of the coolant allows you to achieve the effective operation of the circulation pumps.

The heating circuit of the warm floors is located horizontally and covers a large area. The force that the circulation pump gives to the flow is spent on overcoming linear and local resistances. The calculation of the pump for underfloor heating depends on the diameter, roughness of the pipe, fittings and the length of the circuit.

Wiring diagram for a heating system with underfloor heating

The main calculation parameter is the pump capacity in the low pressure circuit:

N = (P × L + ΣK) / 1000, (m), where

N - pressure of the circulation pump, m,

P - hydraulic loss per linear meter of length (passport data from the manufacturer), pascal / meter,

L is the maximum length of the pipes in the circuit, m,

K is the power factor for local resistance.

K = K1 + K2 + K3, where

K1 - resistance on adapters and tees, connections (1,2),

K2 - resistance to valves (1,2),

K3 - resistance at the mixing unit in the heating system (1,3).

Pressure characteristic of the circulation pump

The degree of performance that a circulation pump has is determined by the formula:

G = Q / (1,16 × ∆t), (m³ / hour), where

Q - thermal load of the heating circuit (W),

1.16 - specific heat of water (Wh / kgS),

∆t - heat removal in the system (for low-pressure circuits 5 ÷ 10 ° С).

Manifold cabinet with connected underfloor heating system

Table 5. The dependence of the unit capacity on the area of heated rooms (for hydraulic calculation of underfloor heating):

| Floor Area, m² | Productivity of the circulation pulser for a heat-insulated floor, m ³ / h |

| 80 ÷ 120 | 1,5 |

| 120 ÷ 160 | 2,0 |

| 160 ÷ 200 | 2,5 |

| 200 ÷ 240 | 3,0 |

| 240 ÷ 280 | 4,0 |

Sector layout of warm floor heating by sector

Mounting diagrams

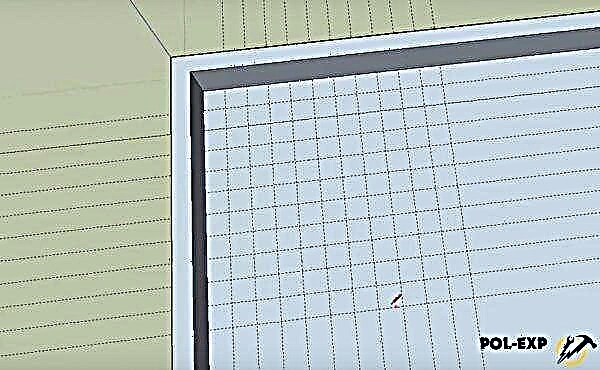

Before planning, you need to calculate the number of pipes required for complete heating of the room. It is recommended for this purpose to use graph paper 1: 50 for drawing a room diagram, as well as for making the necessary calculations

When building a drawing, it’s important to keep the scale

For the correct calculation of pipes per square meter of surface, you need to plan the laying scheme in advance:

"Snake"

. This type of installation is suitable for small rectangular rooms. In most cases, the installation of a snake is used for a water floor as an alternative method of heating. The main disadvantage in this case is the uneven distribution of heat. The highest temperature points are concentrated in places of pipe bends close to the collector. If you move away from the latter, the temperature will drop.

Double "snake"

similar to the previous type. The only difference is in laying not one, but two pipes at once, parallel to each other.

Corner "snake"

involves the exit of pipes from the corners of the room.

"Snail"

It does not have heat loss due to the fact that it combines warm and cold pipes, thereby ensuring uniform heating of the area. Installation is carried out in cold rooms with a large area. The step is up to 35 cm.

When laying a snake adjacent pipes are located at a distance of 30 cm from each other. When approaching doors and windows, this distance is reduced to 15 cm. This position provides pressure reduction and long-term operation.

Based on many years of practical experience, professionals in the field of construction work

The reason for the arrangement of the "warm floor" system is most often an insufficient amount of thermal energy coming from other heating appliances. Before proceeding with the installation of flooring with heating, some calculations should be performed. Including you need to find out how many meters of pipe you need on a warm floor.

In order for such a system to correspond to its functional purpose, it is necessary to perform the calculations as accurately as possible. It is better to entrust this to professionals, but you can find out how many pipes go to the underfloor heating yourself if you familiarize yourself with the relevant information.

How to choose the diameter of the heating pipe

It will not work out exactly what section of the pipe you need. You have to choose from several options. And all because the same effect can be achieved in different ways.

It is important for us to deliver the right amount of heat to the radiators and achieve uniform heating of the radiators. In forced circulation systems we do this with pipes, coolant and a pump

In principle, all we need is to “drive off” a certain amount of coolant for a certain period of time. There are two options: to put pipes of a smaller diameter and to supply a coolant with a higher speed, or to make a system of a larger cross section, but with a lower intensity of movement. Usually choose the first option. And that's why:

- the cost of smaller diameter products is lower

- working with them is easier

- when laying open, they do not attract attention so much, and when laying on the floor or walls smaller strobes are required,

- with a small diameter, the system contains less coolant, which reduces its inertia and leads to fuel economy.

Since there is a certain set of diameters and a certain amount of heat that needs to be delivered through them, it is unreasonable to consider the same thing every time. Therefore, special tables have been developed, according to which the possible size is determined depending on the required amount of heat, the speed of the coolant and the temperature indicators of the system. That is, to determine the cross-section of pipes in the heating system, find the desired table and select the suitable section from it.

The calculation of the diameter of the pipes for heating was carried out according to this formula (if you wish, you can count). Then the calculated values were recorded in the table.

The formula for calculating the diameter of the heating pipe

D is the desired diameter of the pipeline, mm

∆t ° - temperature delta (difference between supply and return), ° С

Q - load on this section of the system, kW - the amount of heat determined by us, required for heating the room

V - coolant speed, m / s - is selected from a certain range.

In individual heating systems, the velocity of the coolant can be from 0.2 m / s to 1.5 m / s. From operating experience it is known that the optimal speed is in the range of 0.3 m / s - 0.7 m / s. If the coolant moves slower, air jams occur, if faster, the noise level increases significantly. The optimal speed range and choose in the table. Tables are designed for different types of pipes: metal, polypropylene, metal-plastic, copper. The values are calculated for standard operating modes: with high and medium temperatures. To make the selection process more clear, we will analyze specific examples.

Determination of the desired room temperature

The final indicator of the floor temperature depends on what purpose the room is used for. For example:

- + 29-30 degrees - halls, hallways,

- + 27-29 - cabinets, living rooms,

- + 30-35 - floors near windows, on verandas,

- +32 - bathrooms, bathrooms,

- + 17-19 - gyms.

Installation of water floor heating

In this case, the temperature of the coolant should not be less than +40 degrees or exceed +60. The heating system should be such that the difference between the temperature indicators of the direct and return pipes in the case of water floors does not exceed 15 degrees. Otherwise, the base will be heated completely unevenly.

The thermal / hydraulic load balance for the water floor must also be optimal and balanced. Therefore, the heating circuits must have a certain length in accordance with the diameter. The optimal version of the pipe is 18 mm, because even with a small amount of water, such a pipeline will work correctly and heat the base.

Heat loss calculation

Typically, underfloor heating systems do not act as the only source of space heating, but some people plan to heat the house just like that. But before making this engineering decision, it is important to make sure whether it is possible to heat a particular room in this way only.

Electric underfloor heating

If during the use of the system the heat loss does not exceed 100 W / m 2, then the underfloor heating system will be enough to warm the room. However, it is rather difficult to make calculations in order to obtain the necessary data, since complex formulas are used. So it is recommended to use the online calculator for calculating the heat loss of the room. If the heat loss exceeds 100 W / m 2, then the thermal insulation of the room needs to be improved or an additional heating system should be equipped.

Calculation for different types of premises

In each room, depending on its features, a different power of floor heating is required. It should be greatest in cool rooms, as well as on a loggia or balcony. In such a room, the power cannot be less than 180 W / m 2. In the bathroom or the bathroom - at least 140 W / m 2 due to high humidity values.

On a note! The power of the underfloor heating system cannot be low if there are unheated rooms under the equipped room.

As for the electric floor, in this case, the minimum power should be equal to 120 W / m 2.

Electric tiled floor

Table. The power of the floor heating system when used as an additional heat source.

| Room | Power, W / sq m |

|---|---|

| Balcony and loggia | 180 |

| Bathroom, bathroom | 140-150 |

| Living rooms and kitchen located on 2 and higher floors | 120-130 |

| Living rooms and kitchen located on the 1st floor | 140-150 |

How to calculate the electric floor heating

In general, the floor heating system consists of several elements. This is a temperature regulator that helps to control the level of floor heating, a temperature sensor that monitors how heated floors are, a heating element, as well as a power cable for connecting all this equipment to the mains.

The temperature controller is usually mounted on the wall, all wires are connected to it. The warm floor itself, as well as the temperature sensor, are arranged under the floor covering (in the screed or on its surface, depending on the type of system - a heating mat, IR film or heating cable).

Touch programmable temperature regulator

On a note! The easiest way to install it is the IR floor or heating mats. They can be laid simply under the floor covering. But the electric cable will have to be filled with a screed. And the step between the wires in this case will have to be considered independently.

For the arrangement of cable heating, a single or two-wire cable is used. The first is the simplest, but at the same time difficult to work, albeit cheap. It will be quite difficult to calculate all the parameters for it, since both ends of the cable must be displayed in one place. And the electromagnetic field from it is formed extensive.

Two-core cable for underfloor heating

It is simpler to buy a two-core cable, which, although it costs a little more, is nevertheless due to the special arrangement of wires easy to install and operate.

Calculation Formulas for Electric Floor

Determining the power of a warm electric floor system is simple.To do this, it is enough to multiply the power of 1 m 2 of the selected system by the area that it will heat. By the way, the amount of cable used is already measured and marked in the purchased kit. The distance between the turns of the wires should be 5-20 cm. It can be exactly calculated by the formula h = Sх100 / L, where h is the desired step width, L is the cable length, and S is the area of the room.

We calculate the electric floor heating

How to calculate a warm water floor

Let's see how many materials will be needed to equip a water heating system in a room. The calculation of the number of pipes per 1 m 2 in this case is as follows: you need to find out how much heat loss in the room will be. They are most easily determined using the online calculator, which contains data on the structure itself, as well as on weather conditions on the street. Let them be equal to 80 W / m 2. The area of the apartment where the underfloor heating system will be equipped, we take equal to 80 m 2. As a result, the total heat loss can be found by multiplying two values of 80x80 = 6400 watts. It is this value that will have to be compensated using all heating systems with a power reserve of up to 20%.

Water floor heating

Table. Calculation of the pipe depending on the step of the loop.

| Step cm | Consumption, m. P. / 1 sq. M. |

|---|---|

| 10 | 10 |

| 15 | 6,7 |

| 20 | 5 |

| 25 | 4 |

| 30 | 3,4 |

Typically, the distance between the conduits is maintained at about 15 cm with a pipe cross section of 16 mm. Then the power of 1 m 2 of the floor will be about 100 watts. Dividing the total area of the room by the step size, we get: 80 / 0.15 = 533 m. It is just so many meters of pipes that will be needed to equip the water heating system in this apartment. The length of each contour is approximately calculated in the same way.

Attention! Near the walls of the room adjacent to the street, the step will be slightly smaller (10 cm). With this in mind, the meter of the conduit is calculated.

Pipes of a certain length, from 50 to 240 m, are on sale in construction stores. They are wound into bays. And to join the entire system to the collector, you will have to buy larger diameter water conduits.

Additional calculations

Consider how the calculation of the hydraulic. It is necessary to determine the power of the purchased pump. Losses for a straight pipe 10 m long, 16 mm in diameter and 2 mm wall thickness will be 1600 Pa. 180 degrees rotations - 40 Pa each. Then, for a room with an area of 18 m 2 with a length and width of walls of 5.6 and 3 m, respectively, when installing a water floor system with a snake, the hydraulic losses will be 18 680 Pa. The figure was obtained by the following calculations: the width of room 3 is divided by a step of 0.15. It turns out 20 straight pipe sections. Losses of all direct sections: 20x5.6x160 = 17 920 Pa. On the corners, the GP will be 19x40 = 760 Pa. Thus, adding up 760 and 17 920 Pa, we obtain a value of 18 680 Pa.

Pump Manifold

This means that for the system to work correctly, it will be required that at least 2.4 l / h of coolant passes through 1 m of its length. You can accurately calculate performance like this: coolant flow rate RTN = 0.86xMK / RT, where MK is the circuit power in kW, RT is the temperature difference in the supply and receiving section of the pipe. Based on the above calculations, a pump is useful for that room, which can pump 0.172 m 3 / h (0, 86x2 / 10).

Calculation Example

Let's look at a simple example of how to calculate the heated area and the power of the electric floor in the kitchen, which is located on the ground floor. The floor will be used as an additional source of heat. The area of the room is 10 m 2. It is required to subtract from it the areas occupied by the refrigerator and furniture - 0.36 m 2 and 2.4 m 2. When laying the contour, it is worth retreating from the walls by about 5-10 cm - this will be about 0.5 m 2. Thus, we get 10 - 0.36 - 2.4 - 0.5 = 6.7 m 2. This value is equal to the floor area under which electric heating will be equipped. For a kitchen located on the ground floor (that is, a cold basement is located at the bottom of the room), subject to additional heating, a floor power of 140 W / m 2 will be sufficient. Now you need to multiply the area of the heated floor 6.7 m 2 by 140 W / m 2. It turns out that the power of the heating system should be 930 watts.

DIY floor heating calculation

Calculation of the length of the underfloor pipe using SketchUP

Step 1. The program draws a room layout with an indication of its size and doorways.

A room layout is drawn.

Step 2 The layout of the room is marked with a grid with the desired pitch of the pipe.

Layout grid

Step 3 On the grid, a pipe layout diagram is drawn.

The layout of the pipes of the warm floor

Step 4 To more accurately calculate the flow, the corners in the diagram are rounded.

Then the corners are rounded

Step 5 Now it’s enough to select the entire route and see its length.

The length of the track is determined.

Calculation of all indicators of a warm floor, including pipe lengths, power and much more - a process that requires a responsible approach. The quality of the work will depend on how accurate the results are.

Anton Svistunov Chief Editor

Do you like the article?

Save so as not to lose!

Calculation table in a private house

Warm floor can serve as the main source of heating in the room or as a means for heating only the floor surface. Depending on what specific functions it is planned to assign to the warm floor system, and its heat transfer is calculated. In addition, the input data are also the geometric and structural characteristics of the room. First you need to find out how much heat will be lost due to the design features of the room. Without knowing this parameter, it is impossible to understand how much heat the heating circuit should give, which is what the calculation is oriented towards.

Only after this step you can pick up the remaining system parameters, such as:

- required pump power

- power of an electric boiler or gas boiler,

- material and thickness of coolant tubes,

- contour length.

In the event that the heating system in the house functions perfectly, and the floor heating system requires only insulation of the floor surface, the main calculated value will be the size of the heated room. The heat loss and the length of the laid pipe circuits of the warm water floor will mainly depend on the geometry of the heated surface. For the calculation to be absolutely accurate, you need to take into account the climate, construction features, number of storeys and much more. The result is a rather complicated thermal calculation.

It may turn out that the consumer is not a professional, but still wants to save on home improvement. In this case, it is possible to use the average heat consumption indicators for private homes. Heating a house with a warm floor has been used for a long time, and experienced specialists have created a special table. It shows the required amount of heat for the intended room in which the heating circuits of the water floor will be placed.

Power formula

In most cases, underfloor heating is used as a system that replaces heating radiators. Then, of course, the calculation will become more complicated, because all factors must be taken into account. In order to be able to heat the entire internal volume of the room, you need to have information about the heat loss of the room. Only after this, knowing the power of the heating circuit, you can begin to design it. So, the calculation itself is as follows:

Mk = 1.2 x Q, where Mk is the necessary heat transfer power of the heating circuit, Q is the same heat loss, and 1.2 is the error coefficient.

From the formula it is clear that the target parameter is the temperature of the coolant in the circuit, to determine which it is necessary to calculate the heat loss. To determine them, you will need to walk around the house with a tape measure. It is necessary to measure the area and thickness of all enclosing objects: walls, floors, windows, doors and so on. To take into account the material structure of all objects, we need a coefficient characterizing the thermal conductivity of individual materials (λ). Accordingly, you need to know from which what is to be calculated is made, whether it is a wall, door or ceiling. All popular building materials and their coefficients are shown in the following table:

Heat loss calculated separately for each protective element of the room, since each object has different properties. The calculation is carried out according to the following formula:

Q = (1 / R) x (tvn-tn) x (1 + ∑β) x S, where R is the temperature resistance of the raw material from which the enclosing structure is made, t is the temperature of the structure, the indices respectively mean the external and internal temperatures, S is the geometric area of the element, β is the climatic heat loss depending on the side of the world, which must be taken into account.

The calculated heat losses for the individual elements are summarized as a result. So, the resulting total heat loss of the room is substituted into the formula for calculating Mk - the heat transfer power of the circuit.

For example, we calculate the required heat transfer of the circuit for a block room of 20x20 m, the width of the walls of which is 2.5 mm. Based on the fact that the thermal resistance of foam concrete blocks is 0.29 (W / m x K), we obtain the calculated value of Rb = 0.25 / 0.29 = 0.862 (W / m x K). The walls are plastered with a layer of 3 mm, which means that Rpcs = 0.03 / 0.29 = 0.1 (W / m x K) must be added to the obtained resistance. This means that the total thermal resistance of the wall is Rst = 0.1 + 0.862 = 0.962 (W / m x K). Next, we calculate the heat loss by the above formula:

Q = (1 / 0.962) x (20 - (-10)) x (1 + 0.05) x 40 = 1309 W.

In the same way, we calculate the heat loss through the ceiling, door and windows. We summarize everything obtained and substitute it in the formula for determining the power of the heating circuit. To the obtained value, add 10%, which will amend the calculation for air infiltration. Any calculator can handle this.

How to calculate the styling?

After you find out the power needed for a warm floor, you can get acquainted with the subtleties of the location of its contour. Further, it remains only to calculate the necessary contour length, which will help to make an idea of the upcoming costs. For clarity, you need to make a sketch on graph paper. The drawing should be made taking into account the pipe pitch and scale factors.

A step is a measured gap of voids between pipes, it must be selected in accordance with several conditions:

- when moving on the floor, the human foot should not feel the temperature difference, So, if the step is too large, then the surface will be heated by strips.

- The step should be chosen so that the pipe performs its function as economically and effectively as possible.

For error-free installation of the pipeline, you need to understand the advantages and disadvantages of the types of installation used. Currently, 4 schemes are used for the installation of the heating pipeline:

- "Snail (spiral)" - The most popular option, because such a laying provides an even distribution of thermal energy. The location is from the periphery to the center with a constant decrease in radius, and then to the other side. When using this method, the step length can be of any size, starting from 10 mm.

Also, this method is the easiest in terms of installation, there are no restrictions in connection with the shape of the room.

- "Snake" - A rather unpopular contour layout method. A huge drawback is that the connection to the supply unit occurs on the one hand, therefore, a significant temperature difference is observed. The surface of the floor will be the colder the farther you are from the boiler. The second significant drawback of the "snake" is the complexity of installation. This arrangement provides for bends of 180 degrees. As a result, the annular pitch should be increased to 200 mm, while 150 mm is considered to be a universal value.

- "Angular Snake." The spread of the warm flow comes from the angle at which the boiler is located. The method is not popular, because the temperature is distributed by a gradient, which, in essence, creates the effect of the "sun". The closer you are, the warmer.

- "Double snake" is a modification of the usual "snake". The difference is that the heat loss is compensated. This is due to the circulation of the flow in both directions. Laying in this way is just as difficult. "Snake" is used for small rooms, such as a bathroom.

All of the above methods can be combined with each other. Small areas are sometimes covered with a “snake”, and elements that do not need to be heated are circled with a “spiral”. Sometimes combined pipe laying methods provide the lowest material costs and minimum investment. Now, having the necessary information, you can begin to calculate the required length of the pipeline. The calculation is carried out according to a simple formula:

L = 1.1 x S N. The above formula reflects the dependence of the length of the heating pipe (L) on the area of the circuit (S), taking into account the step (N). A factor of 1.1 is required to account for pipe stock for bends. At the end, you should also take into account the segments that will connect the installation with the boiler with current and countercurrent.

In order to avoid misunderstandings, we calculate the length of the heating circuit for the living room of 25 square meters. m. In order to remove the restriction in the dimension of the step, we will give preference to the method of spiral laying and choose a step of 0.15 meters. In this case, it turns out that the length of the pipeline being laid is L = 1.1 x 25 / 0.15 = 183.4 m.

Let's say the underfloor heating system works from a comb, which is located 5 m from the circuit. When calculating, it is necessary to double this distance, since the collector has a counterflow. Consequently, the resulting length of the contour will be L = 183.4 + 5 + 5 = 193.4 m.

Professional Tips

Having figured out the calculation, you can go with the results to specialists and specify their task. No need to rush, it will not be superfluous to get acquainted with some nuances. You can encounter them, only installing a warm floor is not the first time. Those who know this matter well recommend:

- When drawing a contour on a drawing, try to figure out how to use as little pipe as possible. With an insignificant length of the pipeline there will be no tangible resistance, and therefore no pressure drops, that is, there will be no need to spend money on a powerful pump.

In general, a short pipe will require less cost.

- When the calculation of the length of the pipeline is completed, the obtained value must be compared with the permissible length of the circuit. It depends on the diameter of the pipe to be laid. If the diameter is 16 mm, then the permissible value of the length of the circuit is 100 m, and if the diameter is 20 mm, then the limit will be 120 m.

- The annular pitch is taken in the optimal range, but depends on the diameter of the heating pipe.

- When designing the installation, you need to remember that not all zones in the room have the same need for heating, so plan windows more closely at windows and door structures. This will provide intense heating there.

- In cases where the projected area exceeds 40 square meters. m, you need to connect a second circuit, since the operation of a single-circuit floor heating in large rooms is inefficient.

Thus, the calculation of the warm floor can be done independently.

It is recommended to perform the calculation manually using the formulas and on a special calculator, and after that - compare the resulting values.

You can find out more information on this subject by watching the video below.